Page 1 of 1

TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 3:50 pm

by Corto Maltese

Hello guys, I would like to inform you here about the progress of my build.

I don't think I could show any new things, as the builders of tw28 have already done such a great job and their posts (Ilker, Allard, Paul, Fabio, Rick, Colin) are very instructive for all us new builders. But not only they, as the Jacques' designs are detailed and advice from the company and all community on this forum are really helpful. I'll post (in bad English) the small details, which, I hope, will be helpful for others.

I came upon the design in the summer of 2011, when I decided to build a boat, which could cruise around the +1300 of Adriatic islands, being sturdy enough to cope with the sudden gales (bora). I was born on these shores where once

Liburnians ruled the waves and as a kid we moved on the foot of Alps, so it is time now, after half a century, to go back to those shores. Maybe I'll give the name to the boat after the Liburnian goddess Ika.

Before you start such a project, you have to consider some issues:

MONEY – you need around 4-5k euros to start the project, then for engine, shaft, propeller >10k, monthly expenses (300 would be more than enouh) and here and there you have to get some extra cash (>1k). You are building this boat not because you want to save money, but because you want to do it and you want exactly such a boat.

TIME – Just a weekend is maybe not enough. I miscalculated somewhat, because I didn't expect so hot summers (over 30 degrees C), when it is impossible to work with epoxy. In these circumstances I can work from March until November, but the “epoxy” temperatures between 18 and 25 I have only from April until June and in September and October. The TW28 is then at least a 4 year project for a guy who relatively owns his time.

PLACE – I have an apartment downtown of

Ljubljana (no backyard for boat builder:). I've had luck to find and rent a place just 10 minutes away walking. I'm paying 150 euros for jutting roof with electricity and some light on the guarded industrial complex. There are trash bins and toilets. The rented place is 18m long and 4,2m wide. I've built some fence around, the first 6 m for my friend's camper and rest of 12 m for TW28. The roof is leaking

DESIGN – It is not enough: you need the support of designer and other builders. Bateau is the gold mine!

PERSONAL – health, family support, tenacity, think everything through, some manual skills (you don't need phd)

When I got the envelope with designs I first built a model from cardboard. It is easier later to understand the structure of boat. And it's fun.

In September I was cruising on my motorcycle around the city looking for a place... and found it in my neighborhood – luck.

In November I made fence around and cleaned the mess. The industry complex is now settled by dozens of small business where once was a huge construction firm which bankrupted. The winter here is cold, always around 0 and down to -10 degrees C. Meanwhile I got okoume plywood (Italian and Dutch, bought in Slovenia), epoxy (German, bought also here) and fiberglass from Germany (around 100 euros for freight).

Then I was just waiting for March 2012 to start with strongback.

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 3:57 pm

by Corto Maltese

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 4:02 pm

by Corto Maltese

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 4:10 pm

by Corto Maltese

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 4:22 pm

by Corto Maltese

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 4:25 pm

by Corto Maltese

July 2012: nada, nothing, rien. Holidays on the island of Cres. Temperatures at home up to 38 degrees C.

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 4:35 pm

by Corto Maltese

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 4:38 pm

by Corto Maltese

September 2012: Gluing the seams and bow. No time for photos. Always in hurry with epoxy. I put some additional patches of FG at the seams near the bow. The forces there are to big to rely only on thin layer of epoxy glue, but maybe I'm wrong... Didn't want to experiment.

Until the end of month I taped the transom seams and bow. The stitches were removed and holes filled with the glue. The temperature fell around 10 degrees C, so it was impossible to tape the seams. They will wait for end of March or April...

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 4:46 pm

by Corto Maltese

November 2012: Drilling screws through the bottom to mark the position for keel molds.

Then bold walkabout with my Makita and here we have a hole along the boat (for the last time, I hope:). With some help of Master Yoda's light saber (laser lever) the keel molds are added.

And then keel panels temporary attached (to hide the hole:). Now, it is starting to be cold and I covered everything until March.

At the beginning of January I realized, that I've done less than planned, but everything done alone and from scratch, without kit, and having hot epoxy-unfriendly summer, I should be content.

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 5:08 pm

by vla

Dario,

Great to read your story, everything you write is so familiar to me. Great to read the enthusiasm of a TW28 builder.

Known problems, known solutions. If you can not do anything because it's winter, spend some time with your wife and child. They will certainly miss you during construction, especially if you do everything on your own.

Nice to see pictures of your boat.

Allard

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 5:24 pm

by Southern Gent

Dario, Man, What a sole project. It looks Great. Work Safe

Re: TW28 for Adriatic Sea

Posted: Sat Jan 26, 2013 6:31 pm

by icelikkilinc

Great report Dario...

keep up the good work.. too hot summers mean milder winters so more time to work with the epoxy

Re: TW28 for Adriatic Sea

Posted: Sun Jan 27, 2013 8:29 am

by Walkers Run

Great job! Thanks for sharing.

Re: TW28 for Adriatic Sea

Posted: Sun Jan 27, 2013 9:24 am

by jorgepease

I can't imagine working in such a tight space, on the other hand if you hang some plastic, a heater might be able to make it warm enough to keep working

Love your meticulous approach.

Re: TW28 for Adriatic Sea

Posted: Sun Jan 27, 2013 4:45 pm

by Corto Maltese

Thank you guys for encouraging words.

In fact I'm tinkering a bit in my living room

In December I bought 4m long 30 cm wide and 5cm thick plank of African sapelle wood and change it into the pile of small 2x9x100cm boards. Now trying to make the Griffiths hatch with

decklight (no idea how to seal it). The rest of the pile will be for next winter. I want to build also a butterfly "hatch" (more like dorado box, without possibility to lift the wings). I hope some photos will come soon.

Yes, the place is narrow, but so am I

and there is 4,2x3,5m free space in front of the bow. Also the 6x4,2m area if I (temporary) remove friends camper, which is also under my roof. 200m away I have a garage for my motorcycle and there I've stored the fiberglass and some other bigger equipment. For now enough space if I take care with my diet.

Dario

Re: TW28 for Adriatic Sea

Posted: Wed May 08, 2013 4:50 pm

by Corto Maltese

It was the longest winter on the sunny part of Alps. Not cold, but lot of snow. So I'm about month behind my schedule

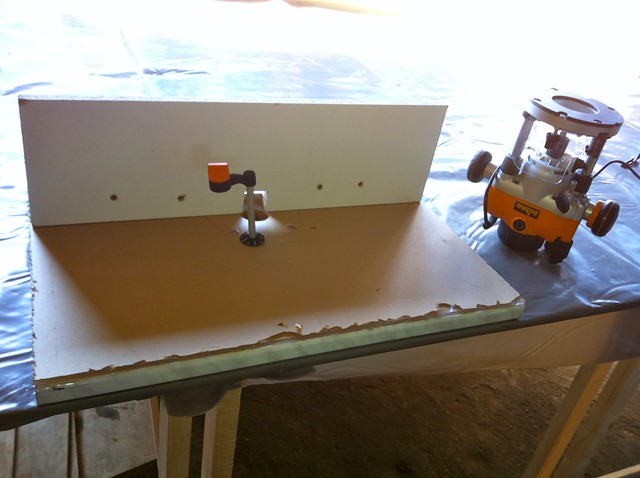

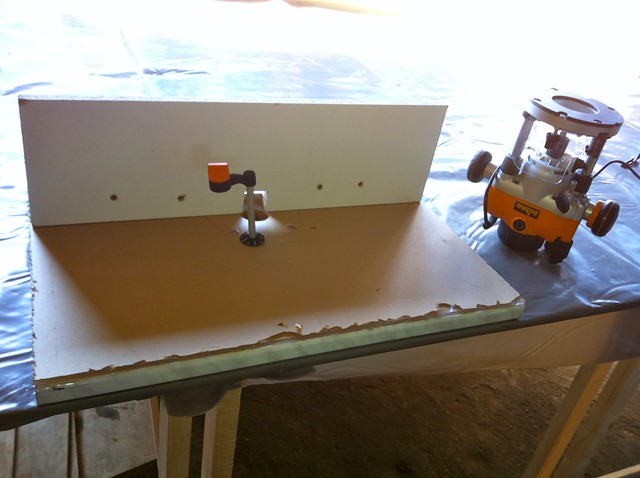

In March I made a 2,5 x 2,5m table. Thought it would be handy later to put somewhere fiberglass, saw bulkheads, collect beer cans and alike. Why the hole on the left?

It is a simple router table

Then I waited for April... and even more snow fell. No conditions for epoxy work.

At the end of month I checked with laser lever the keel, which seemed to me being somewhat awry.

I was wrong.

It was time for reassembling and stitching the keel, putting masking tape underneath and gluing the panels. Most unexciting boat builder photo:

Then the time for mounting the bulwarks came. This was more exciting and I was aware of it from the beginning. The bowside of strongback was in the way of bulwark.

I have a moaning chair nearby. Howard I. Chapelle in his book Boatbuilding from 1941 tells, that such chair is obligatory for every boat building place. So, with help of this chair, chisels and Japanese saws, the solution was swift and the bulwarks are on (You have to trust me. I forgot to took a photo).

Rick asked Allard, how did he connect bulwark with sides... I'll do the same way. It is much easier to follow the good steps of others (and sometimes to learn from mistakes

Re: TW28 for Adriatic Sea

Posted: Wed May 08, 2013 5:15 pm

by Corto Maltese

May and the temperatures kind for epoxy came down here

The seams are taped and the top of keel also. I have to fillet the bottom of keel and taped it. But now, when right temperatures are here I'm short with time. Much work with the students...

I hope I can do everything to start laminating the hull in June.

I've noticed that the second tape is more difficult to wet out. It is tight woven biax and if the temperature is high, there is not enough time to suck the resin. With heavier texture of FG we should use slower hardener. There is also not a recipe what to use - squigees, rollers or brushes. It depends on FG, temperature, maybe humidity...

These days I'm going to wash the hull and tapes, grind and make the rest of taping. But then... before the the start of laminating I will have to use that chair and to collect some beer cans and think over everything.

Cheers,

Dario

Re: TW28 for Adriatic Sea

Posted: Wed May 08, 2013 5:47 pm

by vla

Good work Dario!

I have a chair too. It is an absolute necessety.

Allard

Re: TW28 for Adriatic Sea

Posted: Thu May 09, 2013 6:31 am

by Knottybuoyz

Nice work Dario. It wasn't all that long ago I was in the same situation. Keep going!

I have a chair too, with a stool for holding beer. I prefer to call it 'medicine'!

Re: TW28 for Adriatic Sea

Posted: Thu May 09, 2013 1:36 pm

by Corto Maltese

Knottybuoyz wrote:I have a chair too, with a stool for holding beer. I prefer to call it 'medicine'!

Yes

I prefer Czech "medicine" during day and Irish at evenings.

Re: TW28 for Adriatic Sea

Posted: Thu May 09, 2013 1:54 pm

by tobolamr

I am glad to see you making new progress! Keep up the good work!

Re: TW28 for Adriatic Sea

Posted: Sat May 11, 2013 9:17 am

by Corto Maltese

Thanxs! It's a long way waiting me.

Re: TW28 for Adriatic Sea

Posted: Sat May 11, 2013 9:25 am

by peter-curacao

Beautiful signature you have there Dario!

Re: TW28 for Adriatic Sea

Posted: Sat May 11, 2013 2:43 pm

by Corto Maltese

Beautiful signature you have there Dario!

Peter it is somewhere in Dalmatia (Croatia), but I can't recognize exactly the place, because there are more than 1200 islands.

Re: TW28 for Adriatic Sea

Posted: Mon Aug 05, 2013 5:30 pm

by Corto Maltese

June... the hull was ready for lamination

but there were some preparations to be done.

Cooking? No, I hadn't stored the epoxy properly and there was a 25 kg of hard brick in the can. Hot bath melted it, but this year I'll store it under my bed

First layer of biax was pretty heavy - 606 g/m2 (18 oz/yd2) and I made a simple stands for heavy roll and for vertical support when laminating the sides.

The laminating of sides was very tiresome for me doing it all by myself (8 hours all together). I used the vertical stand with 9x1,27 m of biax.

First I washed the plywood and then worked meter by meter (maybe even less...). I am using only rollers. It works just perfect for me. I needed 2 rollers for each side. First I roll up to 1 m of epoxy on the ply (it's very good okoume). If it is getting hotter and over 25 degrees C (77 F) I worked on shorter distances (around 60 cm). The sides were sticky and it was easy to "glue" the fabric onto the fast vertical sides (you have to smooth it with palms). Then the dance started. I used 200 g of epoxy and 60 g of 30 minutes hardener (it's 9 oz batch). Even there is a hurry, it is not good to roll to much intense as it builds air "foam" between the strands of glass. Afterwards you're chasing the bubbles out of glass and producing the new ones

Epoxy is strange and everybody finds its own way called "The Zen of goo". Beside the advices from Jacques, Joel, Larry and other gurus from this community, maybe the most useful would be the book "How to seduce women" or something alike

My advice would be: Don't work if it is to hot. It is possible with slower hardener but with the temperatures around 30 degrees C (85 F) you'll use to much epoxy and make unnecessary thick layers. But... you guys from south of US, Australia, Carribean, SE Asia and other hot and humid places, have mastered some other secret skills to overcome this issue.

Well, I've managed to glass the hull with first heavy layer. I'm quite satisfied. There were just few bubbles I've ground away and patched them with a piece of cloth. It is worth to plan your working day and have "plan B" if something goes wrong. But all in all the laminating is not much more complicated than the brain surgery. I'm joking... you'll learn very fast your way of doing it.

In June I had not much time, so only this first layer was done. July is usually to hot and we were on the vacancies:

Of course, I was again wrong. July was moderate and now (August) we're living in the hell: every day the temperatures in the city are near 40 degrees C (100 F). We have the highest temperatures for a century after one of the longest winter. Something really strange is happening with the climate (or I'm just getting old).

Never mind: it is time for sanding. And yes, I've ordered 100 kg of epoxy today (1400 euros).

Re: TW28 for Adriatic Sea

Posted: Mon Aug 05, 2013 5:49 pm

by Knottybuoyz

Thanks for the update! Your story sounds all too familiar!

Between the weather, working alone and accidents I'm not much farther ahead. I just laid out the second layer of glass on the sides today. Tomorrow they'll get 'gooped'!

Keep posting updates. It's always nice to see another going through the same agony I am!

Re: TW28 for Adriatic Sea

Posted: Sun Nov 23, 2014 9:32 am

by Corto Maltese

Dear fellows I have to apologize for not posting so long anything about the progress of my build. There are some excuses, but the main reason is, that last year I was really disappointed, because I couldn't achieve my goals. The main reason was the wave of extreme hot weather: the temperatures in August were above 35 degrees C (95F) and hit the record of 42C (108F). Even though we're living at the brink of Alps and not in Sahara. You bet epoxy does not like such environment and the plans for fiberglass lamination were postponed until mid September.

The second layer of woven 282g/m2 FG (8,32oz/yd2) was silky and "runny", the threads tending to get stuck. Masking paper helped:

I stuck with my wetting tehnique: 1. throughly wash the previous FG layer; 2. sand with RO sander and 40 grit paper; 3. vacuum cleaner; 4. wash again; 5. let the surface dry; 6. with 10cm velour roller apply on the hull approx. 1m of epoxy; 7. stick on the fabric and gently smooth with hands (don't forget nitryl gloves); 8. roll over next layer of epoxy; 9. repeat from 6-8 till you drop dead

Didn't use much more than 1:1 epoxy, maybe 1:1,2 , but I'm not sure.

This kind of light fabric was easier to sand and left smoother edges than biaxial.

All work was done alone by myself, with moments of epoxy panic: if over 27C, epoxy coagulating fast, if near 18C being goopy and saturating the cloth to slow

Therefore no time (energy, will..) for taking photos. Luckily there were not many bubbles or other spots to correct.

Next step was 3rd layer of 450 g (13,27oz) biaxial FG. I didn't find 0-90 degree fabric, so I had to put it 45 degree on the hull and overlapping it approx. 15cm. In fact it was much easier than working with 9m long roll of FG. I've done it from the edge of keel down to the sheer line. I always laminated the keel at the end, with FG overlapping tape bonds. That should also add some strength. But the November chill arrived and there was no more time for keel. I covered the hull until the springtime. There are two nuisances in my shop: leaky roof above and stray cats below (I mean, what they leave behind after meals given by a Samaritan girl). The first one I met with plastic cover, and the second ... with broom and some strong words in March.

Re: TW28 for Adriatic Sea

Posted: Sun Nov 23, 2014 10:09 am

by Corto Maltese

I'm not very fond of winters. The town being usually packed by tourists, after Christmas becomes foggy and gloomy. This year there was not much snow, but luckily it's less than hour ride to the first skiing resorts, and the sun above our foggy basin. So, I was happy the time for cleaning all that cat's poo in my shop came. Having a lot work to be done on my job, my family did not have much use of me. I was taking all free moments to make up the “deficit” from last year. Until June the hull was laminated also with 4th light woven layer on the top of biax FG. Sanded and prepared for fairing:

At that time I was quite sick of my trusty RO sanders, the bigger Metabo with turbo switch

and smaller devilish Makita, which I use on the sides, as my biceps are not so big like your former Californian Governor (born 100 miles away in neighbor town) has. How naive I was! The fairing was waiting at me around the corner.

But before fairing hell: Hurrah, the vacancies! I had covered the hull, left shop to the stray cats and went with my family to the seaside for next three weeks.

Before fairing I glued a strip of 12mm plywood, which wood be basis for more decorative rub rail from African mahogany. I won't fair bulwarks and rather gonna try to veneer them with the same kind of wood (+ epoxy, varnish).

I start fairing with a version of Cracker Larry cocktail: mixing usual batch of 200g epoxy and 60g hardener with 8 spoons of microbaloons and 2 spoons of silica. I'm not sure... and there is some need for rum, I think, or is it Ricks variant with beer. Well, you have to get a mayonnaise and spread it with squeegee over the hull. It covers the texture and the edges, where FG has been overlapped.

The “CL mayonnaise” worked good and was not difficult to sand. I used it mainly on the bottom and horizontal areas and keeping a pricy fairing putty for vertical sides, because it does not sag. Oh yes: don't use can spray for leading color. I had to wash it down with acetone

I sanded, vac cleaned, washed, applied the putty and merry-go-round again one month (or was it little less than eternity?). With my trusty RO friends, bare hands, and Flexicat tool. I didn't use much putty. There are two different approaches: use a thick layer of putty and sand it down or repeat the job many times filling and sanding the low spots with thin layers. The first one is pricy and faster, but IMO needs an experienced worker. The second way is easier, cheaper (it took me 3kg of 2 compound epoxy putty), but mind cracking dull never ending story.

I want the boat to have a work-boat look, not yacht finish. The main reason is that I'm not professional boat builder and other is, that fancy yachts on east Adriatic have to pay anchorage for every safe cove, but not so rich boaters maybe can do it with some chat with native guy and a glass of wine (this ancient custom is, of course, dying out). My strategy was to make nice sides and well done bottom. If fish will complain, I'll fry them and drink another glass of wine. At the end of process the result was surprisingly better than I expected. Finally I covered the hull with a layer of unthickened epoxy. And sand it. And vac it. And wash it.

Covered the hull with 2 layers of Hempel's two component light primer. The third should be done at the end of this project, just before paint. There are few pin holes and spots to correct with fairing putty just before this last priming.

At that time I was looking at Ricks preparing and turning of boat. My way should be closer to Colin's. Bought for 160 eros of beams and spent a fortune on large Spax screws and start with another project with any experiences. Luckily the frame was much stronger than needed. I don't know what I was waiting for. Going around the caged boat, adding more pricy screws and reinforcing battens.

Then 12th November, ta-dah:

http://youtu.be/WifADhn7n-A or

https://vimeo.com/124430395

Now, the boat is again covered against leaky roof and shop at the disposal to stray cats until next spring.

Re: TW28 for Adriatic Sea

Posted: Sun Nov 23, 2014 10:19 am

by Cracker Larry

Amazing work

That is a heck of a project to tackle, you are handling it well !

Re: TW28 for Adriatic Sea

Posted: Sun Nov 23, 2014 10:58 am

by terrulian

Didn't know Pete Seeger was a sailor.

Anyway, the heavy equipment approach! The video makes it look a little less stressful than knottybuoyz but I'm sure it wasn't.

I'm blown away with you guys building the big boats, by which I mean anything bigger than ten feet, which seems like a plenty big job to me

.

Re: TW28 for Adriatic Sea

Posted: Sun Nov 23, 2014 4:18 pm

by jacquesmm

Very nice job, thank you for posting.

Turning the hull is big moment, a turning point.

Pete Seeger has an album with some excellent shanties, I like "What shall we do with drunken sailor" and "Deep Blue Sea".

Re: TW28 for Adriatic Sea

Posted: Sun Nov 23, 2014 9:10 pm

by Knottybuoyz

Congratulations on the successful flip Dario. Cheers!!!

It certainly is a nice feeling isn't it? And the boat seems a lot bigger now too!

Oh what I would have given for some heavy equipment like you had. So much easier. Very soon it'll all be a faded memory.

I hope you're ready, the real work starts now! Keep the updates coming.

Regards...

Re: TW28 for Adriatic Sea

Posted: Mon Nov 24, 2014 7:18 am

by Corto Maltese

Thank you for encouraging words! It would be impossible without the knowledge treasury on this forum.

The bigger fork-lift and operator cost me 100eur for 2 hours (the firm is just 75m away), the little one was friendly help from neighbouring shop.

I found Seegers sloop on Youtube. Didn't know about shanties, but we can for sure add some new verses to Drunken sailor (about epoxy haha).

I'm reading Tony's book. Got it on Kindle. 2 brave and witty guys...

Cheers,

Dario

Re: TW28 for Adriatic Sea

Posted: Mon Nov 24, 2014 9:47 am

by terrulian

Knottybuoyz said,

Very soon it'll all be a faded memory.

Wow, I doubt that!! I don't think either of you will ever forget it. A tale for the grandkids.

Thanks for buying the book. Only downside with the Kindle version is you can't burn it in a beach campfire while listening to Jimmy Buffett and hoisting a few.

Re: TW28 for Adriatic Sea

Posted: Fri Jun 05, 2015 11:41 am

by gonandkarl

Hallo Corto,

Thanks for the encouraging wishes for not too hot weather here in Austria. It is crazy, first it was all the time cold and raining so definitely no epoxy work and now it is too damn hot that one can only mix 150 grams of it. I have no slow hardener and therefore I battle along with small batches.

I just had another look at the flipping of Your boat. I must say it really was fast. Will you also have to put 2 part foam into the bottom of your boat ? If so dont buy it in 400 ml bottles to shake like I did, rather in big ones which you can apply with a pistol.

Greetings from Karl ( Austria )

Re: TW28 for Adriatic Sea

Posted: Fri Jun 05, 2015 4:40 pm

by Corto Maltese

Karl,

after the record hot summer of 2013 I don't want to risk any more time and so I use epoxy BLH200 (Germanische Lloyd approved) and fast hardener K25 also with the slow hardener W400 (

http://www.ebalta.de They have seller in Austria, which supplies also Slovenia and Croatia). The slower W400 needs a whole day to harden, but I mix them 1:1 and it gives me comfortable hour to work with 250g batches. Especially filleting is now easier. You can mix these hardeners in different ratios. Downside of this epoxy is that it is measured by weight (100gE:30gH), but I'm used now. I noticed also that if it is cold and humid it tends to form some amine blush which clogs the sanding pads. Nevertheless you can remove it easily with water.

No foam needed for tw28

Grüß aus Laibach,

Dario

Re: TW28 for Adriatic Sea

Posted: Wed Jun 10, 2015 4:09 pm

by deuce_454

will you be coppercoating the bottom (copper powder and epoxy) it is rock hard and is a permanent antifouling paint that doesn't pollute

Re: TW28 for Adriatic Sea

Posted: Thu Jun 11, 2015 8:24 am

by Corto Maltese

I'm not sure for coppercoat, although I checked it on net.. I have at least 2 years time to decide

I'm not sure about pollution, because it is copper like in many other antifoulings. And coppercoat also disolves slowly.

Of course I'm for eco-consciousness; Northern Adriatic is shallow (<30m) and heavily polluted from Veneto industry, Pad farming, too much tourism from Venice to Istria...

Re: TW28 for Adriatic Sea

Posted: Thu Sep 01, 2016 1:59 pm

by gonandkarl

Hallo Dario,

When will we see again pictures of your boat ? I hope you are progressing well.

To the last question about copper for the bottom of your boat my opinion is that epoxy/graphite does a really good job on the bottom which I have tested with my FS13 by dragging it over a pebble beach at the Traunsee and it has no scratch.

Greetings from Karl

Re: TW28 for Adriatic Sea

Posted: Thu Sep 01, 2016 3:48 pm

by Corto Maltese

Karl,

thanks for neighbourly concern

Didn't post anything, as Rick is doing all the job for me. He's few weeks ahead of me. At the moment I'm fixing the engine bearers, next week we're going to put the engine with the fork-lift into the hull. I have to make small trolley and move engine 3 m forward, hoist it with chain pulley and then carefully lower onto the engine mounts.

Next step will be fixing the Python drive and then I can measure and purchase 35 mm shaft etc., and later propeller.

It seems my way at this moment separates Rick's, who's fixing skeg and rudder..

I don't have much time for making posts on this forum, but I promise to make a youtube of engine mounting.

Wish you all the best and visit me in Laibach if you have chance. It would be the opportunity for me to clean the mess in my "shipyard".

Cheers to all boat builders on this tiny third rock.

Re: TW28 for Adriatic Sea

Posted: Thu Sep 01, 2016 5:18 pm

by jacquesmm

If you do a search on google, you"ll find that the copper in epoxy does not work. For it to work, the paint has to break down and release the copper but epoxy does not break down. No copper gets released = no anti-fouling.

If it worked, we would sell it.

Re: TW28 for Adriatic Sea

Posted: Thu Sep 01, 2016 10:39 pm

by TomW1

jacquesmm wrote:If you do a search on google, you"ll find that the copper in epoxy does not work. For it to work, the paint has to break down and release the copper but epoxy does not break down. No copper gets released = no anti-fouling.

If it worked, we would sell it.

Epoxy coats the copper not allowing it to be released to the water. You need a true bottom paint. There are several formulations available that will work. Some last a year or two, some last 3-4 years.

Re: TW28 for Adriatic Sea

Posted: Fri Sep 02, 2016 3:57 am

by Corto Maltese

In fact I have a long way to antifouling, but deuce_454 posted a question here about copper coat..

The efficiency of antifouling depends of the environment. I believe, that "my" Adriatic is not so problematic as tropical waters (including Florida), where you have to use strong poisons. There was an interesting test of various antifoulings in Practical Boat Owner few months ago. They tested various products all over the British shores, with quite different results.

What concerns copper coat. Of course it is uneficient, when somebody just lets it on the hull. Because the copper is encapsulated within the epoxy, you have to dive and rub it frequently or even lightly sand to expose copper. The ordinary antifouling does it by itself (it's for us, lazy guys), and you have to put on new layers each year or two. But there are rumors of some new technologies arriving...

Copper coat works for someone somewhere and for others don't. The heated polemics on the Cruisersforum are nevertheless amusing for me.

Now, I'm going to my boatyard to drill 8 12mm holes for engine mounts onto bearers. The antifouling is still a galaxy far far away for me

Re: TW28 for Adriatic Sea

Posted: Thu Oct 26, 2017 2:32 am

by gonandkarl

Hallo Dario,

We are waiting already a long time that you show us pictures of your boat. Even that I build a sail boat I like the TW28 a lot and follow all the builds of it.

Greetings from your neighbor Karl

Re: TW28 for Adriatic Sea

Posted: Sat Oct 28, 2017 1:50 pm

by Corto Maltese

Dear Karl,

my build is slowely advancing; the bulkheads are fitted, the frame for sole is ready, brackets for water heater, two 120l diesel tanks, two 70l water tanks (the flexible 120l will be under the bed, also for weight) and are gued inside. I painted this section with bilge paint, drilled a hole and fixed it for marelon through hull for cooling water intake. Not more than an hour work to connect it with the filter and engine. Tomorrow I'm going to drill the hole into the transom for bronze exhaust and then all is ready to connect it to gooseneck, silencer and waterlock towards the engine. 130 euros for 4m of Vetus exhaust hose

and the plastic parts I've mentioned were over 300 euro. Luckily I forgot the price of that bronze part

This section needs about 3 hours of work. That will be all for this season.

Yes, I promise to put some pictures soon. I have a shortage of time: work, family etc. I'm also working in a very tight space and the pics won't be a state of the art. I hope we'll continue with tw28 build together with Rick as soon as the spring comes. Meanwhile at least three months of winter hibernation (and collecting some euros for epoxy, fiberglass, plywood...).

Wish you all the best,

Dario

Re: TW28 for Adriatic Sea

Posted: Tue Oct 31, 2017 12:41 pm

by TheBroomside

One step at a time, and suddenly the next TW28 will hit the water. THX for the update. Happy hibernation

.

All the best,

Peter

LUS

Re: TW28 for Adriatic Sea

Posted: Wed Nov 01, 2017 9:45 am

by Knottybuoyz

Nice work Dario. I hope to catch up in the spring. Stay warm this winter.

Cheers!

Re: TW28 for Adriatic Sea

Posted: Sat Jun 04, 2022 1:46 pm

by Corto Maltese

August is a deadline, but most probably September, or ...

Re: TW28 for Adriatic Sea

Posted: Sat Jun 04, 2022 2:00 pm

by fallguy1000

...more pictures please

Re: TW28 for Adriatic Sea

Posted: Sat Jun 04, 2022 9:44 pm

by glossieblack

Impressive progress since you last post some 5 years ago! Congratulations.

Re: TW28 for Adriatic Sea

Posted: Sun Jun 05, 2022 3:25 am

by TheBroomside

Looks good. Nice work!

Peter

LUS

Re: TW28 for Adriatic Sea

Posted: Thu Jun 23, 2022 3:50 am

by Corto Maltese

I'm posting the question also here:

Finally, I'm going to buy a propeller now for the TW28. But... there's no exact answer and I'm a little bit confused.

I have a Beta Marine 43hp (Kubota) 2800rpm engine with TMC60 (2.54) and a Python Drive in front of the 35mm axle. Now, Jacques proposed a long time ago a 17"x13" propeller for a similar engine and transmission, but the dealer suggests to me 19"x17". I wanted a 19" 3-blade propeller as there's enough room.

I checked different online pitch calculators and I'm even more puzzled. The data ranged from 19"x11" to 19"x14" and one calculated the same 19"x17" dimensions as the dealer offered. So, maybe this last dimension could work.

But I would like also to ask for real experiences from builders and practical people as obviously there's no hard science working here. Especially because the hull of TW28 with box keel is not common.

Wish you nice summer on your boats or successful boat building.

Dario

Re: TW28 for Adriatic Sea

Posted: Thu Jun 23, 2022 6:48 am

by glossieblack

Does the prop supplier offer a re-pitching service for a fee? If so, suggest you go with the largest practical diameter, and a somewhat conservative pitch. Use it for a season, gather data, and then re-pitch if required.

Re: TW28 for Adriatic Sea

Posted: Thu Jun 23, 2022 8:11 am

by Corto Maltese

glossieblack wrote: ↑Thu Jun 23, 2022 6:48 am

go with the largest practical diameter, and a somewhat conservative pitch. Use it for a season, gather data, and then re-pitch if required.

That sounds clever, thnx

Re: TW28 for Adriatic Sea

Posted: Thu Jun 23, 2022 1:49 pm

by Fuzz

glossieblack wrote: ↑Thu Jun 23, 2022 6:48 am

Does the prop supplier offer a re-pitching service for a fee? If so, suggest you go with the largest practical diameter, and a somewhat conservative pitch. Use it for a season, gather data, and then re-pitch if required.

Glossie is spot on. You do not want to over prop the engine as that is a good way to kill it. Fully loaded boat with all the weight it will ever carry and the engine should still reach full rated RPM. You do need to be a little close on the prop as there is a limit to how far a prop can be re-pitched. For a 19-20 inch prop you need about 3 inch clearance. I would go with the biggest dia prop I could swing.

Re: TW28 for Adriatic Sea

Posted: Thu Jun 23, 2022 3:00 pm

by TheBroomside

Dario,

I have a very similar setup: 42 HP Mitsubishi, TMC60 with 1:2.5 reduction, Python drive and 35 mm axle.

The propeller is 19x13. Cruising speed is app 10 km/h at 1700 rpm. At 800-900 rpm speed is 6 km/h. For manoeuvring a lower speed would be easier, so perhaps the pitch is a little high. On the other hand the 1700 rpm is a good compromise with regard to noise, so I am not really considering changing anything. With this setup the Luka needs a little less than 1,5l/h which is quite nice considering current diesel prices.

I do not think the setup can handle a 19x17 prop, to me me the pitch is way too high.

Good luck, looking forward to a splash.

Regards,

Peter

Lus

Re: TW28 for Adriatic Sea

Posted: Thu Jun 23, 2022 11:37 pm

by TomW1

Dario totally agree with Luka you do not want to over pitch this your motor.

Tom

Re: TW28 for Adriatic Sea

Posted: Fri Jun 24, 2022 8:04 am

by Corto Maltese

Thanks for the excellent advice,

yes, I've also doubted the suggested pitch. I'm expecting cruising speed around 5kn and enough thrust for sudden gusts of bora, the strong wind falling from mountains toward the Adriatic sea.

Peter, I have just one question more... do you reach max rpm? (in my case 2800)

I wish I could drink a beer with you

Re: TW28 for Adriatic Sea

Posted: Sat Jun 25, 2022 8:47 am

by vla

TheBroomside wrote: ↑Thu Jun 23, 2022 3:00 pm

Dario,

I have a very similar setup: 42 HP Mitsubishi, TMC60 with 1:2.5 reduction, Python drive and 35 mm axle.

The propeller is 19x13. Cruising speed is app 10 km/h at 1700 rpm. At 800-900 rpm speed is 6 km/h. For manoeuvring a lower speed would be easier, so perhaps the pitch is a little high. On the other hand the 1700 rpm is a good compromise with regard to noise, so I am not really considering changing anything. With this setup the Luka needs a little less than 1,5l/h which is quite nice considering current diesel prices.

I do not think the setup can handle a 19x17 prop, to me me the pitch is way too high.

Good luck, looking forward to a splash.

Regards,

Peter

Lus

Dario,

I have the same engine as Peter, only mine have a 30mm axle. My prop is 16x14 . The cuisine speed is 10 km/h at 1600 rpm and uses 1.6l/h. So my conclusion is: no difference. But my feeding says that a 19 inch prop can transfer the power beter in the water. Max rpm +/- 2500 2600 with a lot of norse and a speed of +/- 14km/h.

Allard.

Re: TW28 for Adriatic Sea

Posted: Sat Jun 25, 2022 10:56 am

by Corto Maltese

Thank you, Allard!

I needed your advice. Now I'm more confident.

I hope I'll get a good price, some producers want from me over 1000eur...

regards

Dario

Re: TW28 for Adriatic Sea

Posted: Sat Jun 25, 2022 2:37 pm

by TomW1

Corto you have gotten some good advice, the info I have through my prop calculator I would go with the 19x13. It will provide you the most thrust and control. 1000 euros while high does not sound high for a bronze prop. A SS 19x13 here in the states would cost $4-600 US. Bronze is always more expensive.

Tom

Re: TW28 for Adriatic Sea

Posted: Sat Jun 25, 2022 4:31 pm

by Corto Maltese

Thank you for your advice, Tom,

the prices a few years ago were 350 eur (it's almost the same as $), I hope I'm getting it now for around 700. The prices include around 22% of taxes, in US the system is different, the taxes are lower, but the merchant margin could be way higher.

Wish you a pleasant Sunday

Dario

Re: TW28 for Adriatic Sea

Posted: Sun Jun 26, 2022 7:10 pm

by TomW1

Corto Maltese wrote: ↑Sat Jun 25, 2022 4:31 pm

Thank you for your advice, Tom,

the prices a few years ago were 350 eur (it's almost the same as $), I hope I'm getting it now for around 700. The prices include around 22% of taxes, in US the system is different, the taxes are lower, but the merchant margin could be way higher.

Wish you a pleasant Sunday

Dario

Good for you, 700 sounds much more reasonable. I know taxes in Europe are higher than here in the US, it is just something that has to be.

Tom

Re: TW28 for Adriatic Sea

Posted: Thu Dec 07, 2023 12:23 pm

by Corto Maltese

It's about time to finish this build. I've hoped to splash the boat in June but some health issues prevented it. I worked hard all summer and we were ready to move to the seaside in September. The first problem was the too-low roof for a mobile crane to access:

...so we have to build an additional cradle and pull the boat out:

And here she is for the first time under the sun:

It was only 110km to the destination, but the truck and crane took me 1100 euros. Never mind, I was still happy to move after more than a decade under the same roof.

And here we are! On the dry dock in Izola Marina on the north Adriatic Sea.

Let's put some antifouling:

Done. BTW the guy on the boat was born when his father started with this build

As you can see, the cockpit is very functional

Re: TW28 for Adriatic Sea

Posted: Thu Dec 07, 2023 12:46 pm

by Jeff

Congratulations, great looking boat!!! Jeff

Re: TW28 for Adriatic Sea

Posted: Thu Dec 07, 2023 1:00 pm

by Corto Maltese

Re: TW28 for Adriatic Sea

Posted: Thu Dec 07, 2023 1:39 pm

by Corto Maltese

I have to express my gratitude to Jacques for the design of TW28 which suits my expectations and for the help in the time of the project. The build would be much more difficult if there was no such support from the bateau community.

Merry Xmas and Happy New Year

Dario

Re: TW28 for Adriatic Sea

Posted: Thu Dec 07, 2023 4:35 pm

by glossieblack

What an exciting post to open. Boat looks great! Well done.

Re: TW28 for Adriatic Sea

Posted: Thu Dec 07, 2023 6:16 pm

by TomW1

Dario congratulations on your launch. It has been a long time coming next spring hopefully you will be able to start enjoying and cruising on her.

Regards, Tom

Re: TW28 for Adriatic Sea

Posted: Thu Dec 07, 2023 11:01 pm

by Fuzz

First of all it has been a long haul for you and my congratulations on the launch!!

I loved the pictures from pulling it out from the work shed all the way to the water. I hope you have a wonderful time with the boat and keep posting about your trips.

Re: TW28 for Adriatic Sea

Posted: Fri Dec 08, 2023 9:02 am

by pee wee

Wonderful to see your build get to the water!! She looks right at home, ready to provide many years of service. Beautifully done.

Re: TW28 for Adriatic Sea

Posted: Sun Dec 10, 2023 2:22 am

by gonandkarl

Congratulations Dario on the successful launch of your boat. As with all of us it took longer to build as the estimated building time. I thought I would finish my boat in one Year seeing that Salvatore in Australia managed to build his Adelie in one Year. It turned out that I splashed only after 5 Years. Think of it like that. Your son can enjoy the boat at the present age lots more as if you finished it when he still was a toddler. Again congratulations and keep posting with lots of pictures from your trips on the Adriatic sea.

Re: TW28 for Adriatic Sea

Posted: Sun Dec 10, 2023 11:24 am

by colinhart

Congratulations I am so jealous. I hope to get mine in the water next year. Enjoy cruising in your lovely boat.

Re: TW28 for Adriatic Sea

Posted: Sun Dec 10, 2023 1:36 pm

by OlivierP

Beautiful boat and very impressive project, I can hardly imagine what you have been through. Congratulations and happy sailing !

Re: TW28 for Adriatic Sea

Posted: Sun Dec 17, 2023 6:40 am

by Corto Maltese

Thank you for your best wishes! It is so optimistic for me to see where these good wishes come from. This forum and Jacque's projects joined us from all the troublesome worlds. We have more in common than the politicians (and the media) try to convince us.

Keep building

Dario