Page 1 of 1

C17 (Classic 17) in London

Posted: Wed Apr 20, 2005 6:59 pm

by WobblyLegs

Well guys, I'm finally starting the real boat!

Last year I built a 1:10 scale model of the boat to see how it all fits together -

More images of this model can be found at :

http://gallery.bateau2.com/thumbnails.php?album=287

Last Thursday I took delivery of a load of marine ply...

...which at some point I am hoping will become a BOAT!!!

I will keep adding pictures to the gallery for "Jack-a-Doodle" (I think this it what the boat will be called) in the gallery at:

http://gallery.bateau2.com/index.php?cat=12964

I will keep in touch.

Wobbly.

Posted: Thu Apr 21, 2005 12:10 pm

by Dane_Ger

Looks like you are all set . . . . keep us posted with your progress!

Posted: Thu Apr 21, 2005 10:44 pm

by Steve_MA

That looks like excellent work on the model. I wish I could make one of those. Can you describe how you did it (if you have the time and inclination). How long did that take?

Posted: Fri Apr 22, 2005 5:58 am

by WobblyLegs

Steve_MA wrote:That looks like excellent work on the model. I wish I could make one of those. Can you describe how you did it (if you have the time and inclination). How long did that take?

Steve, thanks for your comments...

I basically followed the original plans and construction technique. I re-drew the plans on a computer (my plans are metric, so I just added a decimal point before the last digit e.g. 76mm becomes 7.6mm). I'm actually finding marking out the full-size plans onto the ply easier than the computer transfer.

The only deviation from full size was the order of doing the joining. I started with the transom, added the motorwell sides and bottom, then frame E to give a stiff box at the rear to start joining hull panels to. In other words I never made a mould for the hull: the panels formed the shape quite naturally when bent to join the edges. I will add a couple of images later that will illustrate this quite clearly.

The bottom panels went on first, using super-glue to "stitch" the keel before joining with glass and epoxy. All still very flexible at this point.

I then super-glue stitched the frames to the bottom panels, to mould the sides around. They got broken out later to enable me to seal the inside. There are more pix in the album now.

Then the lower sides, followed by upper sides. All seams were glassed with a strip about 10mm wide, inside and out, as per full size (although only one layer) after which internal frames were added back in to the structure. I was still a bit concerned with the flexibility of the structure at his stage.

Next, the whole of the bottom and small overlap onto the lower side was glassed (one layer). I have added an image of this to my album. After that I added the deck and the entire structure "suddenly" become extremely rigid and strong. A sigh of relief.

The decking effect is made of small 0.2x5mm wood strips, spot super-glued in place and then painted over with epoxy. I'm still undecided if I am going to repeat this on the full size boat, but I would like to. It depends on whether I can find suitable wood that won't add too much weight and if I have the inclination (and time as I'm on a summer deadline due to this all being built outdoors!) when that point arrives.

The entire boat is put together using 0.3mm and 0.8mm plywood from my local model shop.

The fairing was done with a hi-fill primer aerosol spray (model shop again), sanded, then sprayed with model enamel, sanded and polished (still haven't finished that to my satisfaction). Now, when I look at and feel the hull, it actually seems like it's moulded in plastic.

All done, I suppose I spent about a year putting it together, restricted mainly by having to wait for epoxy to set on every join before proceeding to the next one, and not being able to work on it indoors during the winter. It would be nice to have a workshop, but space is scarce for those kind of luxuries over here.

I hope this is all clear enough, but any other questions, feel free to ask. I know I'm going to be posting plenty of questions myself as the real boat goes together.

Regards,

Wobbly

Posted: Fri Apr 22, 2005 3:49 pm

by glcost

WobblyLegs,

Your C17 model looks wonderful. I'm impressed with the level of detail you went to, like glass and epoxy of the joints.

One suggestion for your cockpit decking in case you can't find suitable planking. Jacques sells marine ply with the outside layer of teak. You could use this and route grooves to give it the look of planking.

George

Posted: Fri Apr 22, 2005 6:30 pm

by WobblyLegs

glcost wrote:I'm impressed with the level of detail you went to, like glass and epoxy of the joints.

Thanks George,

I really just wanted to see how it all went together, using the same techniques as the full size boat, and hopefully it will be strong enough to run a REALLY fast RC motor on! As it progressed, it just seemed natural to try and make it look nice.

BTW, I can grab the bow and stern of this little thing in my hands and try to twist or bend it: not possible!! Credit to the designer!

glcost wrote:One suggestion for your cockpit decking in case you can't find suitable planking. Jacques sells marine ply with the outside layer of teak. You could use this and route grooves to give it the look of planking.

George

I saw that on the site, but he's in Florida and I'm in UK, so not really practical. I'm not actually too worried about the looks of the boat inside the cockpit (probably paint it white there), but thinking of doing the upper-deck in this style.

Regards,

Wobbly

Posted: Fri Apr 22, 2005 8:17 pm

by glcost

Yeah, I found building the model made me pay close attention to all the details of the plans and building process, although I skipped the glass and epoxy. Something I wanted to do before taking on the full scale project, plus I immensely enjoyed building the model.

I saw you are in London and assumed Jacques' European branch would carry the same marine ply, but looking at the site I don't see it.

http://europe.boatbuildercentral.com/index.php

Also, most of the exotic marine ply comes from Europe. The okuome I bought came from Greece and France.

Anyhow, it was just a thought I had for mimicking the look of wood boards without adding weight.

Posted: Sun Apr 24, 2005 7:54 am

by WobblyLegs

glcost wrote:Anyhow, it was just a thought I had for mimicking the look of wood boards without adding weight.

Thanks for the idea, George. I was thinking of laying thin strips side by side to create the effect, but after thinking a bit about your suggestion of routing out through a teak finished ply, perhaps it might be easier for me to laminate a thin veneer and the make grooves afterwards for the decking effect.

Like I said earlier, I'll decide when the time comes. There is still an awful lot to do before then.

Wobbly

Posted: Sun Apr 24, 2005 11:52 am

by Steve_MA

You can also by ply that looks like planking.

www.boulterplywood.com has teak and holly ply that isnt totally out of sight price wise. I dont know what you can get where you are.

Thanks for the explanation on how you built your model. I am thinking of building a C17 one day and thought i might try it myself, but i can see it would be a big job.

Update: 24 April 2005

Posted: Sun Apr 24, 2005 2:44 pm

by WobblyLegs

Well, I have now measured all the 9mm ply (10mm on the plans) except for the stringers. I was hoping to cut it all this weekend, but it rained all Saturday, and the weather was so good this morning that we had to go out for a nice 100mph bike ride!!! Oops.

I have changed the nesting supplied, as I wanted to create frames that were all going to be used later in one piece. See the pic, with explanation under:

The supplied nesting was 10 sheets of ply, which meant that frame D was split into 3 pieces, and frame C was bisected vertically. I felt that by adding one more sheet of wood, I could split frame C at the deck line horizontally (which means I can build the hull closer to the ground), and keep frame D as one piece for the moulding (cabin side to be cut out of it later).

Personally, it's a small cost with a big ease-of-use advantage for one extra sheet of plywood.

Also, it leaves me with quite a lot of large off-cuts to use later for building a console and other little bits of woodwork that I'm sure to encounter.

Anyway, hopefully I will be able to start cutting all this wood during the week and next weekend, hoping to be able to set up the mould framework by the end of the weekend (it's a 3-day weekend for us here!).

More to follow, I'm sure,

Wobbly

Posted: Tue May 03, 2005 6:51 am

by WobblyLegs

Well, a busy weekend for me.

I have managed to cut all my 9mm panels (with the exception of one cabin side which will come out of frame D after rollover), and the stringers.

I've left the stringers for last as I want to laminate some of the longer lengths of off-cuts together so that I can measure (and cut) them as one piece instead of trying to get everything to fit together later. It makes sense to me...

So far the only error I found was when I laid the two motorwell sides together to match them, and found that I had measured one sloping upwards towards the transom and one sloping downward towards the transom.

So, not a panic, as I have lots of large off-cuts, and was able to cut a new one without a problem.

I only hope I haven't made any other errors in measuring.

If the weather holds (thunder showers predicted for today!) I'm hoping to laminate what will become the stringers tonight and cut them tomorrow or the next day, and also laminate all four transom pieces before the weekend, leaving me ready to begin building the mould on the weekend.

As before, I have uploaded some more pic's in my C17 album.

http://gallery.bateau2.com/thumbnails.php?album=286

Wobbly.

Posted: Thu May 05, 2005 5:48 pm

by WobblyLegs

Well, I had to wait a couple of days as the weather isn't co-operating, but I have managed to laminate the stringer wood tonight.

http://gallery.bateau2.com/albums/userp ... 00x400.jpg

I have decided that it's probably better not to post pic's of everything I do here, so I'll keep the pic's in the thread to major development (like the next one hopefully will be the frames/mould), and just put links to the "minor" pic's (which are in my gallery).

Posted: Thu May 05, 2005 8:24 pm

by Cracker Larry

So far the only error I found was when I laid the two motorwell sides together to match them, and found that I had measured one sloping upwards towards the transom and one sloping downward towards the transom.

Just a suggestion for anytime you are cutting mirror image pieces. Stack the two pieces together, secure with clamps or screws, then cut as one piece. They will always match, you only have to lay it out once and cut it once.

8 May

Posted: Sun May 08, 2005 2:54 pm

by WobblyLegs

So, this weekend has been a little more relaxing, but still keeping ahead of my schedule.

Stringers laminated, measured and cut, in that order, then notches cut. Followed by notches cut into frames "C," "D" and "E."

I had to check whether they all fit:

It's also the first real indication of the size of the boat that I'm building. Somehow a tape across the ground showing 17 feet doesn't mean anything!

I had planned on laminating the transom, but got hit by a thunder-storm with hail like I have never seen (in England) before… (20 minutes after this pic was taken, the sky was black. Unbelievable!).

More pic's in the gallery as usual.

Re: 8 May

Posted: Wed May 11, 2005 9:57 pm

by BillTwo

WobblyLegs wrote:So, this weekend has been a little more relaxing, but still keeping ahead of my schedule.

Stringers laminated, measured and cut, in that order, then notches cut. Followed by notches cut into frames "C," "D" and "E."

I had to check whether they all fit:

More pic's in the gallery as usual.

Wobbleylegs, I posted earlier to your thread in a differrent category but I didn't get your response. This is the perfect one that I really wanted.

I'm now waiting on my Pre-Cut Plywood Kit to begin building my OB17. While waiting, I was practicing notch cutting using my table saw and jig saw (I do have a Bandsaw, but its still in the box). Both tools did not give me the quality of notch cut that I was looking for. I had to use my wood chisel on one or two, and fine trim some other notch cuts due to undercuts, and splinters. My question to you is

HOW DID YOU GET SUCH PERFECT LOOKING NOTCHES for those frames and stringers? What tool(s) did you use and how did you use them? Woodworking is not my best suite and the only project that I've ever built in my life was birdhouses.

Any instructions or details on how you did yours would be greatly appreciated.

If you would like, you can email me the information, but any details on cutting those notches correctly would be of great help to me. I've use masking tape to reduce the splinters but I still have a poor quality cut notch when I finish cutting. Whether it be on my table saw, which causes an overcut. I have a general purpose blade (60 tooth blade) on my table saw and my Jig Saw has an all-purpose blade that can be used for cutting Plywood. The Table Saw is a Craftsman, the Jig Saw is Black & Decker and my BandSaw is a Delta (which I haven't used yet).

Regards,

BillTwo

Re: 8 May

Posted: Thu May 12, 2005 4:39 am

by WobblyLegs

BillTwo wrote:HOW DID YOU GET SUCH PERFECT LOOKING NOTCHES for those frames and stringers? What tool(s) did you use and how did you use them?

Hi BillTwo,

Sorry, I never saw your question in the other thread (once I had an answer for that one I kinda forgot it was there, and didn't have a "notifier").

Regarding the notches, I measured the widths to EXACTLY 9mm on the stringers and 18mm on the frames (stringers are 2 x 9mm ply). My stringers are 122mm high so I made the 60mm deep on the stringers which turned out to give me 62mm to be cut out of the frames.

As to cutting, I used a jigsaw, taking it slowly and making sure that the measured line stayed on the centre of the blade (i.e. taking out about 1mm [half the blade width] or so of wood either side of the line). Doing the end of the notch was a bit crude: after cutting each side of the notch to full depth, I started about 2/3rds of the way in on one cut and cut a curve heading towards the end of the other cut. I then cut straight in to the line of the notch-end repeatedly and SLOWLY shaving away the edge of that curve, basically using the jigsaw as a "file" to square off the end.

Does this make sense?

The notches are NOT a tight fit which is the way it needs to be. You need some space for epoxy to glue the frames to the stringers at a later stage. In my case I'm guessing at just under 1mm on either side as my jigsaw blade cuts a width somewhere between 1 and 2mm or so.

I'm using a plain "high-speed" cutting blade, and am getting some splinters as you do, but they are small and I just brush them off (it's all getting covered eventually).

I hope this all helps, but I'm really not the expert on this forum. I'm basically working out how to do stuff as I get to it. I seem to be improving though

Posted: Thu May 12, 2005 8:58 am

by Steve_MA

As he said, you dont want the joints to be tight..you want epoxy to get in there. Almost any mess you make at this point with the saw can be fixed with epoxy...so long you dont cut the stringer in half

I think the biggest headache might be if you cut the nothes too deep. But even there you could use a clamp/wood block to keep it at the right height and tab it with epoxy.

Re: 8 May

Posted: Thu May 12, 2005 11:37 am

by BillTwo

WobblyLegs wrote:

Hi BillTwo,

As to cutting, I used a jigsaw, taking it slowly and making sure that the measured line stayed on the centre of the blade (i.e. taking out about 1mm [half the blade width] or so of wood either side of the line). Doing the end of the notch was a bit crude: after cutting each side of the notch to full depth, I started about 2/3rds of the way in on one cut and cut a curve heading towards the end of the other cut. I then cut straight in to the line of the notch-end repeatedly and SLOWLY shaving away the edge of that curve, basically using the jigsaw as a "file" to square off the end.

Does this make sense?

The notches are NOT a tight fit which is the way it needs to be. You need some space for epoxy to glue the frames to the stringers at a later stage. In my case I'm guessing at just under 1mm on either side as my jigsaw blade cuts a width somewhere between 1 and 2mm or so.

I'm using a plain "high-speed" cutting blade, and am getting some splinters as you do, but they are small and I just brush them off (it's all getting covered eventually).

I hope this all helps, but I'm really not the expert on this forum. I'm basically working out how to do stuff as I get to it. I seem to be improving though

Thanks Wobblylegs, that's just the input that I needed. When you are a novice at something and you try to do those things that you haven't done before, its always great to get that experienced help you need to keep you going in the right direction.

As I indicated before, I was practicing with two different tools to cut notches; using a Table Saw and then a Jig Saw. Now I just have to improve on using my Jig Saw. Every thing that you explained to me made sense. Also, it jogged my memory about gaps are good - especially for epoxy, as long as its within the given tolerances. I was trying to make a near tight fit less than 2mm. My gaps were coming out around 5-6mm. In terms of

US measurement, I want to keep my cuts down to 1/8 inch or less but not so tight as to defeat the epoxy glue.

Thank you so very much for your input and I too will post some more of my pictures on the Gallery as soon as I have something to Post. Currently it's just a model concept that I plan on incorporating on the OB17 once I get my Pre-Cut Plywood delivered. I can be searched on the Builder Galleries under "OB17".

Steve, thanks for your input also. I will keep a close eye on my gaps when doing my Stitch and Glue process.

Regards,

BillTwo

Re: 8 May

Posted: Thu May 12, 2005 11:54 am

by WobblyLegs

BillTwo wrote:Also, it jogged my memory about gaps are good - especially for epoxy, as long as its within the given tolerances. I was trying to make a near tight fit less than 2mm. My gaps were coming out around 5-6mm. In terms of US measurement, I want to keep my cuts down to 1/8 inch or less but not so tight as to defeat the epoxy glue.

Hello again BillTwo,

I seem to recall reading somewhere (either on the Bateau site, or in my plans) the the gap must be no more than 1/8 in TOTAL, so only 1/16 on each side (remember we're talking notches here - other parts of the boat allow bigger gaps). I've been looking at some of the tutorials since my first reply, and they suggest cutting with your blade on the outside edge of the line.

Have a look here:

http://bateau2.com/content/view/77/28/

You'll get better with the saw as you progress - I'd cut all my 9mm before doing the notches, and am now confident enough to cut most curves to within about 1mm (1/16?) of my line. When I started I was about 3-5mm out.

Good luck.

W.

Posted: Thu May 12, 2005 2:02 pm

by Cracker Larry

Hi BillTwo,

As to cutting, I used a jigsaw, taking it slowly and making sure that the measured line stayed on the centre of the blade (i.e. taking out about 1mm [half the blade width] or so of wood either side of the line). Doing the end of the notch was a bit crude: after cutting each side of the notch to full depth, I started about 2/3rds of the way in on one cut and cut a curve heading towards the end of the other cut. I then cut straight in to the line of the notch-end repeatedly and SLOWLY shaving away the edge of that curve, basically using the jigsaw as a "file" to square off the end.

That's one way to do it. Here's another......drill a hole slightly larger than the jig saw blade just inside one of the corners. Make your first cut to the corner with the hole, then use the hole to turn the saw 90 degrees to make the back cut.

As to splintering, the plywood will splinter pretty bad cutting cross grain. To prevent this, put down a strip of masking tape where you will cut, lay out the line on the tape then cut with the tape in place. No splinters.

Re: 8 May

Posted: Thu May 12, 2005 5:14 pm

by BillTwo

WobblyLegs wrote:BillTwo wrote:

Have a look here:

http://bateau2.com/content/view/77/28/

You'll get better with the saw as you progress - I'd cut all my 6mm before doing the notches, and am now confident enough to cut most curves to within about 1mm (1/16?) of my line. When I started I was about 3-5mm out.

Good luck.

W.

WobblyLegs

That is exactly what I remembered about the 1/8 inch. You want believe how many times that I've read that tutorial. My problem was what tool was best for doing this?

Now that I know what tool to use, and how it should be used to cut the notches, I will perfect my skills on scrap plywood until the real thing gets here

You answered my question in that last thread that you so kindly wrote me. I will be perfecting my cuts with both my table saw and jig saw and using my Jig Saw as my tool of choice for my notches.

Cracker Larry

Thanks for your advice with the drilling of the holes. Somewhere, I did read about drilling holes in a corning but the explaination and details were not as clear as yours. I will try that first thing when I get home. Thanks

Regards,

BillTwo

Posted: Sun May 15, 2005 5:39 pm

by WobblyLegs

Well, it's been a good weekend (no rain) so have managed quite a bit.

After a bit of a panic on Friday:

http://forums.bateau2.com/phpBB2/viewtopic.php?t=8213 I started to assemble the mould, which has worked out very well.

Getting everything in the right place wasn't easy, but modern equipment helps:

And this is what I ended up with this afternoon:

Surprisingly, still ahead of my schedule, but then again, I haven't started sanding yet!!

As usual, more pics here:

http://gallery.bateau2.com/thumbnails.php?album=286

Regards,

Wobbly.

Posted: Sun May 15, 2005 11:18 pm

by DrBones

Looks like you're well you your way, Paul!

I've been looking forward to someone documenting the build of a C17.

One thing though I would keep a secret from whomever tends to that lawn...well, I don't think it will survive the mistreatment it will get

Wobblylegs C17 Construction

Posted: Mon May 16, 2005 12:58 am

by BillTwo

WobblyLegs wrote:Well, it's been a good weekend (no rain) so have managed quite a bit.

After a bit of a panic on Friday:

http://forums.bateau2.com/phpBB2/viewtopic.php?t=8213 I started to assemble the mould, which has worked out very well.

Getting everything in the right place wasn't easy, but modern equipment helps:

Surprisingly, still ahead of my schedule, but then again, I haven't started sanding yet!!

Regards,

Wobbly.

Wobbly, keep doing what you are doing. It looks great to me and I see that your area of construction seems to be in your back yard. Hope the weather holds up for you. I'll be starting my OB17 within the next 2-3 weeks, as soon as my Plywood arrives. Your efforts to keep us posted on your progress and sharing with us your mistakes are commendable. I am already learning from you some things before I begin my OB17 construction; method used for cutting notches, what things to remember when epoxying and your efforts to maintain a tight tolerance in your building of your C17.

I also read your thread on the Transom gluing concern and the methods in which it was resolved. Your construction details and the posting of pictures, with comment, to the gallery is like reading a good novel - you can't wait to get to the next chapter.

Wobbly, keep up the good work and don't let mistakes take you away from your objective of building yourself a first rate boat. I hope to do the same.

Take care,

BillTwo

Posted: Mon May 16, 2005 7:39 am

by WobblyLegs

DrBones wrote:Looks like you're well you your way, Paul!

I've been looking forward to someone documenting the build of a C17.

Yeah it feels like I'm building now, and that the last month or so has merely been "preparation" if you know what I mean by that? Up until last Friday it all just looked like an Ikea flat-pack! I'm surprised by the size of it, although it is just right for what I want. BTW, dunno where you got "Paul" from, the name's Tim.

I'm enjoying keeping a record of progress here - I've found the site to be very useful for me, so maybe others can also learn from my mistakes as well.

DrBones wrote:One thing though I would keep a secret from whomever tends to that lawn...well, I don't think it will survive the mistreatment it will get

Ah, the lawn is my domain - the flowerbeds are "her's" so as long as I don't trample the flowers I should be OK.... Still it took a lot of persuading to get permission from SWMBO to build it there. I'm sure there is going to be a boat shaped path worn into the ground very soon.

Later,

Wobbly. (Tim)

Posted: Mon May 16, 2005 11:54 am

by Dane_Ger

Wobby, Looking good!

I'm also pleased to see you documenting this boat due to your building outdoors . . . I'm going to have to build my next one outdoors also, so I'm following with great interest the steps you are using to align and level everthing!

I'm sure there is going to be a boat shaped path worn into the ground very soon.

I was sweeping out the garage yesterday and I have a nice outline of epoxy drops on the floor in the exact shape of my boat.

Dane

Posted: Sun May 22, 2005 3:35 pm

by WobblyLegs

So, here we are then...

The weather this past week has been rain-sun-rain-sun-rain!

Still, I managed to measure (Friday) and cut (Saturday) the bottom hull panels. Saturday was really frustrating 'cos I had to pack everything away 3 or 4 times when the rain came. But, I managed to get the panels cut.

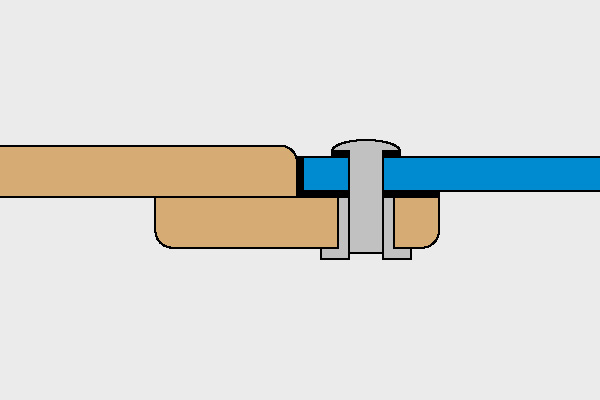

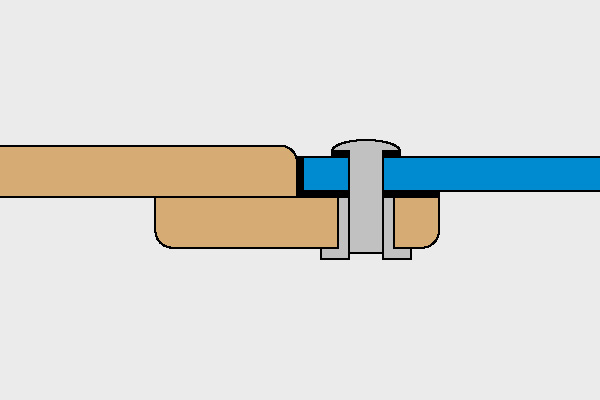

Then, today I joined the fore and aft sections of the panels together. As you must know by now, I'm building in my garden - so I don't have any nice flat surface to work on. My work-around on that is to make what I'm now calling my "joining-boards."

Basically, a strip of ply, lots of screws, turn it over and epoxy-glass the other side. The plastic in-between is so that the "joining-board" doesn't end up being glued to the panels.

I know it's strong enough, as I went indoors, came out 10 minutes later to find one had been blown off the frame onto the ground (it's been windy too), and all was still aligned!

Anyway, it's now glassed on one side, tomorrow I will do the other side and hopefully start stitching the bottom together the day after!

Wish me luck!

Wobbly.

C17 Classic - London

Posted: Tue May 24, 2005 4:02 pm

by BillTwo

WobblyLegs wrote:

Anyway, it's now glassed on one side, tomorrow I will do the other side and hopefully start stitching the bottom together the day after!

Wish me luck!

Wobbly.

Wobblylegs, just a few words- Since you are building outdoors, under a tent. What I've been reading while waiting on my OB17 Pre-Cut Plywood is the concern about moisture. I'm sure you are too. Don't forget those edges while glassing the other side. You are doing perfect quality work from what I see and I just thought that I might add that just in case.

Regards,

BillTWo

Re: C17 Classic - London

Posted: Tue May 24, 2005 5:52 pm

by WobblyLegs

BillTwo wrote:What I've been reading while waiting on my OB17 Pre-Cut Plywood is the concern about moisture. I'm sure you are too.BillTWo

Hi Bill,

Yeah, I have been concerned about moisture, but circumstances are what they are. I have to deal with it, or not build a boat...

Hopefully, by leaving the sides off the tent, there will be enough airflow around the whole thing to prevent condensation, etc.

Anyway, I decided against glassing the other side of the bottom panels, and went ahead with stitching them on the frame (the join is in a relatively low-stress area, and the stress will be on the outside anyway, so I didn't see the point in adding another day or two to the project).

So far, looking good:

Keep well,

Wobbly.

Posted: Thu Jun 02, 2005 4:35 pm

by WobblyLegs

Forming the hull.

Well, it's been a bit longer than usual since my last update, but it's all been a bit boring, really.

Until now.

I've joined the lower side panels together (pic's in the usual place) and have spent the past week or so (after work) stitching the bottom and lower sides together.

And un-stitching, re-stitching, un-stitching, etc., etc.!

Here's the result so far:

I have to say, everything is starting to fit together

extemely well. I hope it continues this way.

Anyway, I'm feeling quite knackered right now, so I will leave it at that for now...

Later,

Wobbly.

C17: The boat-shaped hedgehog

Posted: Thu Jun 02, 2005 11:28 pm

by BillTwo

WobblyLegs wrote:Forming the hull.

You can see here the the ends of the stringers don't meet the back of the motorwell sides - that's 'cos I measured thinking the transom was four layers thick there, not two!

Reminder to self: Add a couple of layers of 9mm ply to the end of the stringers after roll-over!!!

Wobbly.

Wobbly,

I took this quote from you last gallery posting showing the Stern end of your Hull without the Transom. I take it that you're going to wait until you flip the Hull before making the correction to your Stringers? If this is the case, are you concerned about mis-aligning the shape of the Hull when flipped without the Transon epoxied with the rest of the Hull?

Your "Joining Board" technique seems to be ideal for the environment that you're working in. Even though I will be building (I hope) in my Garage, I am considering using the "Joining Board" method. My question is, with all those screws in the board, how time consuming is it to putty-in all those screw holes and approximately how far into the splice do these screws penetrate?

Wobbly, you're an inspiration for me. I can't wait to start on my OB17 (custom) boat. I'm still waiting on my Plywood delivery - should be delivered within the week.

Keep pumping-out those pictures with text. I look forward to seeing your progress.

Regards,

BillTwo

Re: C17: The boat-shaped hedgehog

Posted: Fri Jun 03, 2005 4:03 am

by WobblyLegs

BillTwo wrote:I take it that you're going to wait until you flip the Hull before making the correction to your Stringers? If this is the case, are you concerned about mis-aligning the shape of the Hull when flipped without the Transon epoxied with the rest of the Hull?

Hi again BillTwo,

I am going to join the transom to the hull before roll-over, but the frames, motorwell sides, and stringers aren't joined at this stage. They all come out after the boat has been flipped (is it called a boat at this stage?) so that the inside of the hull can be glassed.

Thats when I'll make the correction to the stringers, before putting them back into the glassed hull.

Keep well,

Wobb.

Posted: Sun Jun 12, 2005 3:59 pm

by WobblyLegs

Getting closer to glass!

Well, the past couple of weeks, I've been joining the bottom and lower-side panels together.

Yesterday I sanded the chines down to a radius in preparation for laying the bi-axial tape (next weekend).

It's still looking good, but to be honest, I'm kinda dreading next weekend.

BillTwo, I don't have an answer about filling screw holes yet, as I haven't done it (leaving it till after rollover). I'm probably going to drip pure epoxy into them, and use a little nail to work the epoxy in to the hole.

As to the depth of the screws: the joining board is 9mm ply, and the panels are 6mm ply. The screws are 16mm, but I haven't counter-sunk the joining board. So, when I screw the boards to the panels, I do it to just a but more that finger-tight (on the screwdriver), and the points of the screws end up just below the outer surface of the panels. Also, holes were drilled into the joining board, but not into the panels - I push-twisted the screws in there.

So, here's looking forward to a fun weekend in 5 days time!!!

Wobbly.

Posted: Sun Jun 12, 2005 4:50 pm

by Yoda

That is really looking good, Wob......... Yessireee!

Getting Closer to Glass

Posted: Sun Jun 12, 2005 10:38 pm

by BillTwo

WobblyLegs wrote:Getting closer to glass!

Well, the past couple of weeks, I've been joining the bottom and lower-side panels together.

Yesterday I sanded the chines down to a radius in preparation for laying the bi-axial tape (next weekend).

Wobbly.

Wobbly,

I don't remember if I asked you this before - did you pre-coat your plywood prior to assembly of the Hull? If you did, did you have any problem bending any of the panels for the stitching and forming of the Hull?

I will be getting my Pre-Cut Plywood delivered hopefully this week. Once I do receive it, I will be applying those recommendation and references such as those from your threads and pictures to my building process.

Continue the good work.

Regards,

BillTwo

Re: Getting Closer to Glass

Posted: Mon Jun 13, 2005 4:36 am

by WobblyLegs

BillTwo wrote:I don't remember if I asked you this before - did you pre-coat your plywood prior to assembly of the Hull?

Hi BillTwo,

No, I haven't pre-coated anything. I wouldn't think that it would be a good idea, as it would all have to be sanded for the glass/epoxy to grip to.

This way, I'll coat the wood, allow it to "soak" for a bit, then lay the glass. I think that starting, say, at the stern with the coating, by the time I get to the bow, I'll be ready to start laying glass from the stern.

Regards,

Wobbly.

Posted: Wed Jun 22, 2005 3:32 am

by kiwi

You are one clean builder! This boat is going to be beauty to behold if you keep this quality throughout.

Tony

Posted: Wed Jun 22, 2005 5:43 am

by WobblyLegs

Okay, so things didn't really go to schedule.

I had no idea how difficult it would be to get the epoxy to wet the glass out. I think maybe if I got a "wetting-out" roller for doing the fabric it might be easier than using a squeegee.

Anyway, I managed to prepare the boat on Saturday - this involved sanding all the joins and lumps of mixture used for filling the cable tie holes etc. Not very pleasant as it hit 36 degrees C (97F) in the garden. Same on Sunday.

Sunday I measured and cut the fabric for the bottom. I also did a few tests and practice fibreglass laminations with the West slow-cure resin/hardener mix that I hadn't used up to now. Just as well, as in spite of using the measuring pumps I found that due to the heat, the hardener becomes so thin that it flows back into the pump! So the method now involves doing a little "primer" squirt from each container into little tubs, then doing the mixing measurements. Having sorted that out, I have to admit that it as real easy to get the right mixture with the pumps.

The other really useful tool that I've discovered is this little cutter:

I had to get my own from the local sewing shop (Mrs Wobbly wouldn't let me use hers) - it's a fabric cutter that I used to cut the glass fabric to fit the hull. All I did was lay the sheets on the hull and walk around it pushing this along the glass - easy, accurate cut. It does need good pressure though!

Monday morning things got delayed (again, weather, a thunderstorm that lasted until about 11). I was only able to start work at about 2 when my work area had dried out enough. I suppose it had to rain, as it was the start of the Wimbledon tennis tournament (and it

always rains during Wimbledon - and it's just up the road from me!

Oh well.

I managed to get the keel laminations done Monday afternoon, followed by the chine laminations done on Tuesday. I also managed to get one layer of tape on the transom, but had to stop there as my last pair of gloves tore. I need to make sure that I don't run out again!

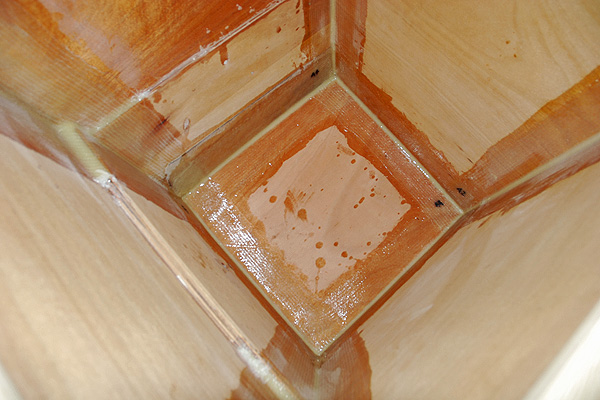

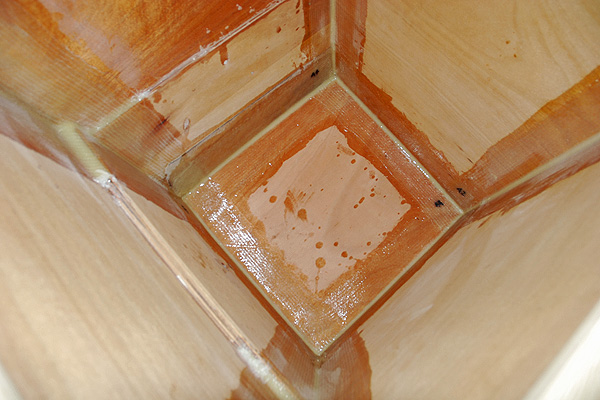

I have to say, I really don't like working with large amounts of epoxy. It's easy enough to spread on a horizontal surface, but on vertical surfaces? Grrr. As you can see from my transom pic (below), it drips all over the place. And sticks to everything. And once it gets on the gloves and squeegee everthing gets all slippery and slimy. And my hands

still feel sticky now, even though I only got a little bit of epoxy on them.

Well, that's about it for now. I now have to sand all those edges before proceeding with the layer of fabric. I'm not going to assume that I will be able to do it all this coming weekend (considering I had thought I could have done it all by now!!). At the very least, I hope to get it all sanded and ready.

kiwi wrote:You are one clean builder!

Tony

Tony, you might not think so anymore after seeing this:

.

That's it for now.

Keep building guys... (BOD's)

Wobbly.

Posted: Wed Jun 22, 2005 9:22 am

by Steve_MA

Hey, it still looks pretty clean. Working with fiberglass/epoxy is messy business. I am on my third box of 100 pr. gloves and still not done with my FL14. It might be late now, but one thing I was thinking of doing next time I build is masking off areas where you dont want epoxy. This might help eliminate the amount of runs and splotches you have to sand off.

It must be a pain having to dodge the weather there...hats off to you! Looks good.

Posted: Wed Jun 22, 2005 9:28 am

by fishingdan

Wobbly, the boat is looking great.

One suggestion....pump epoxy/hardener into measuring cups. The pumps get less accurate over time (also with differences in temps) and with a 5 to 1 ratio, there is less room for error.

Keep up the great work!

Posted: Wed Jun 22, 2005 11:14 am

by Lucky_Louis

Great looking work and pictures Wobbly

. Sounds like we are the same stage, I'm building my OB17 outside and did the tape and hull glass last weekend. Question for you - why did you stop taping the corners half way up the transom? That whole joint is highly stressed by the engine weight and stresses. Maybe check your scantlings or with Jacques before applying the skin glass.

cheers, Lou

Posted: Wed Jun 22, 2005 11:28 am

by jacquesmm

Good looking job but what was the problem with wetting out the fiberglass? Does it stay white? In that case, it may be the binder. Not all types of glass are compatible with epoxy.

Normally, the fiberglass should become transparent in a few minutes if not seconds.

From the pictures, it looks OK now.

Posted: Wed Jun 22, 2005 11:40 am

by WobblyLegs

jacquesmm wrote:Good looking job but what was the problem with wetting out the fiberglass? Does it stay white? In that case, it may be the binder. Not all types of glass are compatible with epoxy.

Normally, the fiberglass should become transparent in a few minutes if not seconds.

From the pictures, it looks OK now.

Hi Jacques,

The glass does go transparent quite quickly, but it took more epoxy than I expected. The problem I had was trying to eliminate all the air bubbles that formed between the weave and it took a lot of repetative squeezing with the squeegee to make sure all the air was expelled.

Regards,

Tim.

Posted: Wed Jun 22, 2005 11:49 am

by WobblyLegs

Lucky_Louis wrote:Question for you - why did you stop taping the corners half way up the transom?

cheers, Lou

Good question Lou - one reason is that with the upper side panels in place I cannot reach the middle of the boat when standing on my little stepladder. Also, I wouldn't be able to work underneath the boat as I wouldn't have enough space to get in - most of my tools and materials are stored underneath.

I'm not concerned about strength as on the coners of the transom (and the bow) the tape goes all the way to the top of the lower side panels. When the uppers side panels are put in place, I will be doing more tape all along that corner, so in effect each corner will end up being a glass-wood-glass-wood-glass laminate for the middle six inches or so (the overlap of the two side panels).

Keep well,

T

Posted: Wed Jun 22, 2005 2:47 pm

by glcost

The hull is looking very nice Wobbly. I like your fabric cutter too; my wife uses one of those for quilting.

On my boatbuilding project last year, I made the mistake of borrowing my wife's sewing scissors. My old shop pair were too dull to cut the FG. She was so pissed at me when she found out. You obviously have better sense then I do.

George

Posted: Wed Jun 22, 2005 2:54 pm

by ArizonaBuilder

I have to say, I really don't like working with large amounts of epoxy. It's easy enough to spread on a horizontal surface, but on vertical surfaces?

When taping, some wet the tape out on a separate table and then put the wetted out tape down on the seams. It is a lot easier then wetting out the tape on the seam.

For a table, I simply use my 12 quart cooler lid. I have put a layer of poly plastic sheeting on the lid. The cured epoxy just peels off as a thin film the next time I am doing a taping session. It is a quick and easy way to tape and the tape has the right amount of epoxy.

Not Meeting Schedule

Posted: Wed Jun 22, 2005 3:40 pm

by BillTwo

WobblyLegs wrote:Okay, so things didn't really go to schedule.

I have to say, I really don't like working with large amounts of epoxy. It's easy enough to spread on a horizontal surface, but on vertical surfaces? Grrr. As you can see from my transom pic (below), it drips all over the place. And sticks to everything. And once it gets on the gloves and squeegee everthing gets all slippery and slimy. And my hands still feel sticky now, even though I only got a little bit of epoxy on them.

Keep building guys... (BOD's)

Wobbly.

Wobbly, your work is still looking good. I shouldn't worry about staying on schedule. Schedules are nothing but references in time as to when you would like for a particular event(s) to occur. The main focus, as I'm sure you are already doing, is detailing and maintaining a good quality of work which you are currently doing.

When I was uploading more pictures to my gallery "OB17 Building Phase", I came across your recent gallery input and saw this strange looking tool with the orange wheel. Now I can rest easy since you explained what it is. I'm always on the look-out for new tools and better ways of doing things.

Finally a word of CAUTION, you mentioned that you "got a little bit of epoxy on" your hands. A little is too much. If you should happen to have that occur again, immediately clean it off with "white Vinegar". This is what I've read in various books and manuals as I'm sure that you have.

I've just now received my Pre-cut Plywood and will begin today cutting out the pre-cut patterns.

Keep up the good work and BOD

Regards,

Billtwo

Posted: Wed Jun 22, 2005 4:08 pm

by jasonmcintosh

Wobbly,

Just wanted to say that it looks like you're doing a fantasic job. The hull looks great. Hope things keep going well for you.

Jason

Posted: Wed Jun 22, 2005 9:46 pm

by JimW

Looks Great!

Posted: Mon Jul 18, 2005 7:10 am

by WobblyLegs

Well, it's been a while since the last update, and things have been progressing slowly.

I think, though, that I'm over the main epoxy hump, that is covering the hull (I know the inside still has to be done, but at least that doesn't have to be fair!).

Since the last update, the weather has really been playing havoc, as for a couple of weeks it seemed to rain every afternoon so I couldn't work in the evenings, and then a couple of weekends too (not as bad as it seems some of you guys in Florida seem to be experiencing, from what I hear).

Anyway, summer seems to have well and truly arrived, so last weekend I managed to sand all the taped seems in preparation for the final lamination, then during the week I measured out the upper side panels (not cut yet).

Then, this weekend I finally bit the bullet and laid the cloth over the boat.

I eventually decided to go "wet on dry" as people here seem to refer to it. Laid down the cloth on the starboard side, positioned it and got on with mixing. Starting at the transom, I just poured the whole lot on the cloth at the centre-line over a distance of about 0.5m (1.5'). As this started to run down towards the chine, I very lightly and without trying to force the epoxy into the cloth, used a squeegee to spread the epoxy over the first area, then went to mix a second pot of goo.

By the time the second mix was ready, I was able to pour on to the cloth again, just below halfway between the centre and the chine, and the first pouring was soaked into the cloth enough to squeeze the air out. After spreading about three areas like this, I had my routine going pretty well.

The port side took about two and a half hours to lay. By now I was on a roll, but it was getting really hot and I was contemplating delaying the second half. But, a half hour break, and nearly two litres of water later, decided it had to go on.

The second (port) side took only one and a half hours to do, working with a nice method:

- Mix one pot, pour at centre and spread towards me (chine) lightly.

- Mix another pot, pour 2/3 of it closer to chine, spread lightly.

- Squeeze first mix to get air out.

- Pour half of remaining mix onto overlap on starboard side and spread lightly.

- Squeeze second batch on the bottom.

- Spread remaining epoxy onto the glass on the side lightly.

- Squeeze starboard side overlap.

- Squeeze side.

- Start again one step closer to the bow.

Measuring and mixing was made easy by having pumps in the resin and hardener that pump proportionally so each pot was four pumps resin, four pumps hardener (about 150ml/5oz). It also helped that the resin had warmed up quite a lot, so was thinner and easier to spread than the first half.

Of course, working in hot conditions did cause a little bit of out-gassing from the wood, but I was able to squeeze almost all of it down again. There are a few very small patches where air got caught under the glass, but looking at it this morning I will be able to grind a small area with a Dremel and squeeze some epoxy into that. Also, having already done the centre and chines, obviously no air could come out there and I have ended up with one very strong looking hull.

It really does look nice now, and as Mrs Wobbly said when looking at the dark wood through the glass, it seems a shame to paint it. I think I have now decided that I am going to try and keep the entire topside natural wood if I can get all the joints neat enough.

Also, I ordered all the wood that I need for the hull trimmings - keel, strakes, spray rail, rub rail laminations - which will be cut to shape (strakes and spray rail) and delivered on Saturday. This week I plan on filling the weave on the bottom in preparation for fairing and hopefully I'll be able to join the keel (skeg?) and spray rails on the weekend.

I shall let you know how I get on (hopefully things will start moving quicker again).

As usual, more pics here:

http://gallery.bateau2.com/thumbnails.p ... 286&page=6

Oh, and I've just noticed that the gallery pics seem a bit out of order, but I'm sure JM will sort that out...

Wobb.

Posted: Mon Jul 18, 2005 6:40 pm

by glcost

Wobbly,

You're moving at an impressive rate even with the weather delays. I'll be following your method on fiberglassing when I get there. Sounds like a good systematic approach when working by yourself.

I have a question for you. How large of a gap did you leave between the hull panels at the bow stem? This weekend I placed the hull bottom panels and the lower side panels. I initial left a 6mm gap where the bottom panels meet at the bow. Placing the lower sides, however, pulled the bottom panel together, so there is very little gap now. I do have a 4-5mm gap between the lower side panels.

When the builder gallery is back online, I plan on starting a progress thread too.

George

Posted: Tue Jul 19, 2005 6:18 am

by WobblyLegs

glcost wrote:Wobbly,

I have a question for you. How large of a gap did you leave between the hull panels at the bow stem? This weekend I placed the hull bottom panels and the lower side panels. I initial left a 6mm gap where the bottom panels meet at the bow. Placing the lower sides, however, pulled the bottom panel together, so there is very little gap now. I do have a 4-5mm gap between the lower side panels.

George

Hi George,

It may or may not be the right way to do it, but I have actually had very few gaps in the boat so far. The only place that I made sure that there was a gap between panels is along the centre-line of the boat and near the front between bottom and lower side panels.

I'm really comfortable with the joins as they are - bottom panels to transom has an angle, so there is a large wedge of epoxy glue in there.

At the front, it took quite an effort to bring the bottom panels together, and that basically forced me to have no gap along the curve (using little cylinders - cut up tent poles - inside, under the cable ties, to stop them overlapping), but the wood (at the edges) touched corner-to-corner, so I filled that groove with a fillet mixture.

With the lower side panels, the same along the chines up until the point near the front where the hard chine started to become flat with the bottom panels, where I put spacers in to force a gap of about 3mm. Where the lower side panels join at the bow, again it was corner-to-corner. I was looking over the plans after I'd filleted this joint and noticed that they say to leave a gap here, but obviously it was too late to change by then. I'm not worried - I can only imagine that my boat will be a couple of millimetres shorter as a result.

As for the bottom panels, again where the angle of join is very shallow, I put spacers in to create a 3mm-ish gap from stern up to the point where it starts curving up to the bow.

With all of these joins, I used a mixing stick to squeeze an epoxy glue (fairly thick) mixture into the gap until I could see it oozing out the other side, making sure there was enough sitting over the join to allow for absorbtion. Then removed cable ties (about a week later to be sure the glue was properly cured) and filled the spaces where they were (and all the holes left behind...).

When I get to laying the upper sides, there will probably be a substantial gap at the bow which suits me, as I'll need to create a flat area for mounting the bow-eye. The rest of the bow there, I will build up a radius of fillet mixture above and below where the eye will be, on top of the fibreglass layers.

Regards, and enjoy building (I am, still)

Wobb.

Posted: Tue Jul 19, 2005 3:35 pm

by glcost

Yeah, my joints are all very tight. Along the keel and chine it's corner to corner between the panels for the most part. I used the bow mold and even there I have very little gap. Even though my hull is very fair, I didn't get the hump in the keel forward of frame C, I think I'll go back through and loosen the ties before gluing the joints.

Not much will happen over the next couple weeks since I'll be on holiday. First, I go up to Edmonton Canada for a rugby tournement then off to Orlando FL.

Take care,

George

Posted: Wed Jul 27, 2005 6:26 pm

by WobblyLegs

So, it's been raining again!

But, unlike the other rain I've had to avoid so far on this project, which have been short showers followed by long, hot, dry spells (usually while I'm in the office!!), over the past two days it's been a light drizzle, fairly warm, and a relative humidity of 98%.

I think you could call it "sticky!"

So, what has this to do with the boat?

Well, the wood has started to absorb moisture and expanded. As I've recently covered the bottom with glass, this is mainly happening on the inside of the boat, and on the side panels. So, as the inside has expanded, the whole boat is changing shape. Not very good!

I don't think it's a real problem, but it is going to be a real delay as the weather is forecast to stay like this for another week or so, and then I will have to wait (hoping) for it to dry out again for me to continue building.

The pic below is of frame C, where - two days ago - the bottom panels and side panels were lying flush against the frame.

And this one is frame D, same again. The gap (again two days ago was flush) is 30mm!!!

I wonder how much moisture this wood can take before causing strain on the joints? I guess I'm about to find out...

Regards,

Wobbly.

Posted: Thu Jul 28, 2005 4:14 am

by esparver

WobblyLegs wrote:

... the wood has started to absorb moisture and expanded

Hi Wobbly,

As you're building outside, why don't you apply first coat of epoxy on the recently cut plywood and then sand the flat pieces before assemply? this is the way I am working with my CR11 right now and I'm sure it will avoid those problems.

I've been following your project very close as I like the C17 boat. You're doing a great job with it.

Regards,

Posted: Thu Jul 28, 2005 8:51 am

by tech_support

esparver wrote:WobblyLegs wrote:

... the wood has started to absorb moisture and expanded

Hi Wobbly,

As you're building outside, why don't you apply first coat of epoxy on the recently cut plywood and then sand the flat pieces before assemply? this is the way I am working with my CR11 right now and I'm sure it will avoid those problems.

I've been following your project very close as I like the C17 boat. You're doing a great job with it.

Regards,

Not a bad idea. But wait for a few dry days first or you will seal in a high moister content.

Posted: Thu Jul 28, 2005 1:45 pm

by Welsh_diver

I am watching this build very carefully as I plan to build a CX19 outside. Since it rains even more in Wales expansion due to moisture absorption is going to be a problem. Would it be possible to pre-coat all the plywood once it has been cut and then assemble the boat as normal?

Posted: Thu Jul 28, 2005 1:50 pm

by tech_support

Yes, you can pre-coat it all. In a very small boat where the curves are more severe, pre-coating might make the wood more difficult to bend – but in your case it would probably be a good idea

Posted: Mon Aug 01, 2005 6:36 pm

by JASmine

Wobbly....Looking at your recent photos I noticed that you are adding the sprayrails before you fair...IMHO it might be easier to fair if you add the spray rails after you fair the hull.

It looks great so far..good luck as you continue.

Posted: Wed Aug 03, 2005 11:16 am

by Deadgobot

Shine wrote:Not a bad idea. But wait for a few dry days first or you will seal in a high moister content.

I thought about posting a question re: this topic on the Plywood board, but since you brought it up...

Do you have to take care to epoxy/fiberglass the plywood in relatively equal humidity conditions? Asked another way, is sealing in different moisture content in different panels a Bad Thing?

For a small boat like my first project, it will be easy to epoxy the whole thing at once, but as I move on to bigger boats the problem will present itself.

Posted: Mon Aug 08, 2005 5:44 am

by WobblyLegs

Starting to make progress again.

Well, after another couple of dodgy weather weeks, things started to turn around about the middle of last week.

Last weekend I managed to join the first two of three pieces of ply to make up each of the upper side panels, and also have made up the spray rails to be attached later. The spray rails are measured and cut to form a point at the front, and are at the moment soaking in a tube full of water, to be put on the boat and moulded soon.

This weekend has been fairly productive, starting with screwing and gluing the keel on on Wednesday evening, followed by removing the screws, drilling out the screw holes and filling them with epoxy on Thursday evening.

Then starting a general clean-up of the hull in preparation for coating of a fairing mixture.

Saturday was spent sanding any remaining lumps and bumps out of the glass covering the hull, tidying the join between the keel and the hull, and final shaping of the keel (planing it so that the bottom is dead level).

Last job of the day was the fairing mixture going on the lower side panels.

Yesterday (Sunday) morning I found that that fairing mixture was still soft (but not sticky) which raised concern about whether I had my epoxy ratio off - I checked the nozzles of my pumps and found that the hardener was a bit clogged up, so was starting to get a bit worried (cue frantic search on this forum for epoxy problems). Anyway, there was nothing to do about it, so I left that, and finished off joining the upper side panels.

I turns out that my panic about the fairing wasn't necessary, as by yesterday evening it was hard and I was able to hand-sand some ridges out. Phew.

One of the reasons for doing the side fairing first is to get a feel for the filler on a relatively small area before doing the bottom. Hopefully I will be able to lay filler on the bottom this evening, trying to make it a bit thinner (the layer, not the mixture) that the stuff I've done so far to keep sanding time down. We'll see. It feels more like cake icing than peanut butter when mixing (slightly gritty). As Mrs. Wobbly has been asking for the past month or so, "when are you starting with the peanut butter?" Well, now I have, and I now feel like I'm on the way to finishing off the hull. Feels good.

Oh, and the wood is finally starting to dry out properly and is returning to it's original shape, lying flat against the frames.

Also, as the side panels are so long, I have nowhere to store them, so I made little hooks out of plywood which are clamped to the transom and frame B, which the side panels are resting on.

The result of this weekends work:

More pic's here:

http://gallery.bateau2.comindex.php?cat=12964

The weather is supposed to be good for the rest of this week, so I'm looking forward to getting lots more done!

Later,

Wobbly.

Posted: Mon Aug 08, 2005 10:49 am

by WobblyLegs

Deadgobot wrote:Shine wrote:Not a bad idea. But wait for a few dry days first or you will seal in a high moister content.

I thought about posting a question re: this topic on the Plywood board, but since you brought it up...

Do you have to take care to epoxy/fiberglass the plywood in relatively equal humidity conditions? Asked another way, is sealing in different moisture content in different panels a Bad Thing?

For a small boat like my first project, it will be easy to epoxy the whole thing at once, but as I move on to bigger boats the problem will present itself.

I don't have the answer for this, but the problem I experienced was due to the wood absorbing moisture on one side only (the other side was sealed) which caused the wood to curve where it could.

All my wood lives outdoors (under shelter) but gets taken off the stack and well aired (both sides exposed) at least a week before being used. This makes sure that the wood is nice and flat.

I would imagine that if there is more moisture in one side than the other, it would

eventually even out in a sealed panel.

I think the most important thing is to make sure the wood is flat (uniformly dry) before working with it, so making it more important to have similar moisture content on each side of the panels, rather than in each panel.

I've said it before: I'm not the expert, but it makes sense to me.

Wobbly.

Posted: Mon Aug 08, 2005 11:27 am

by Deadgobot

WobblyLegs wrote:I think the most important thing is to make sure the wood is flat (uniformly dry) before working with it, so making it more important to have similar moisture content on each side of the panels, rather than in each panel.

I've said it before: I'm not the expert, but it makes sense to me.

Since I'm even less of an expert, until I hear words to the contrary yours will work as passable gospel.

Your boat is shaping up nicely!

Posted: Mon Aug 08, 2005 1:49 pm

by Welsh_diver

Where did you get the gazibo? I would like a photo of the storage method you are using?

Thanks

Posted: Mon Aug 08, 2005 1:58 pm

by PaulMcClure

It looks like one I bought from Homebase a couple of years ago.

Posted: Mon Aug 08, 2005 3:14 pm

by WobblyLegs

PaulMcClure wrote:It looks like one I bought from Homebase a couple of years ago.

It's probably the same - I got it from Argos (part of the same group as Homebase) for about 80 quid. Been very useful.

Posted: Mon Aug 08, 2005 3:56 pm

by PaulMcClure

Yep, sounds like it. I just turfed mine out and bought a new one from Argos for £60+. The old one was a bugger to put up on your own, the new one is really easy, since the frame is collapsible without dismantling.

One caveat for these is that the fabric is not really waterproof, so bear that in mind when leaving it out when rain is expected.

Posted: Mon Aug 08, 2005 4:23 pm

by circlehook

hi wobbly i have been checkin out this site for a while and hope to build the c17 someday. yours is looking really great. any ideas yet how you are going to lay out the interior? paul

Posted: Mon Aug 08, 2005 5:10 pm

by WobblyLegs

PaulMcClure wrote:Yep, sounds like it. I just turfed mine out and bought a new one from Argos for £60+. The old one was a bugger to put up on your own, the new one is really easy, since the frame is collapsible without dismantling.

One caveat for these is that the fabric is not really waterproof, so bear that in mind when leaving it out when rain is expected.

Mine is obviously of the old design then (6x3 metre) - poles that slide into each other, nothing fits perfectly etc., etc.

Yeah, I know it's not waterproof - I cover the boat with a tarp as well (except when I'm leaving epoxy to cure - which is why I need to be confident of dry spells before doing major work like fibreglass on the bottom!!).

circlehook wrote:hi wobbly i have been checkin out this site for a while and hope to build the c17 someday. yours is looking really great. any ideas yet how you are going to lay out the interior? paul

I'm thinking of running benches both sides, far enough forward that it also becomes a seat for me to use with some leg-room while steering. I'm not planning on installing a proper seat - I can always lean on the side if needs be on a long river trip (or hopefully Channel crossing to France!!!). If at sea with biggish waves, I'd prefer to be standing anyway.

But the layout is, as they say, very much subject to change.

And, tonight, I have discovered that I was a bit generous with the fairing mix. When they say "easy to sand" I guess they mean "relative to stone" or something like that. So, new procedure, enough to fill the weave, and if needs be, more later.

The stuff is easier to mix than to sand.

Welsh_diver wrote:I would like a photo of the storage method you are using?

Thanks

I built a deck at the bottom of the garden a couple of years ago, which is where everything is. It's quite protected, surrounded by fence/shed on three sides, but open at the front. What you can't see in the photo is that it has a roof.

The wood lying on the deck is sitting on some 2x2's, so is kept "in the air," while the stuff stacked at the back is mostly off-cuts (but of a size to be used later for a console, or other fittings that I might dream up.

Everything lying flat stays covered with a tarp until ready to use. Usually, if I need a sheet, I'll take it out, stack it near the back with a big air gap for a week, then get on with it.

Nice chatting,

Wobbly.

Posted: Mon Aug 08, 2005 5:33 pm

by PaulMcClure

Yep, that's the one. I threw mine out after having to put it together myself for the millionth time - every time you get one pole in the rest fall apart.

I'm thinking of doing my C17 with a similar layout, but converting the benches to being fish storage, so I can keep them from filling up the floor

A plug at the bottom will aid washing them out.

Commiserations on the sanding. I'm using QuikFair right now (N7 for my daughters) and it's great

Posted: Mon Aug 08, 2005 6:09 pm

by WobblyLegs

PaulMcClure wrote:I'm thinking of doing my C17 with a similar layout, but converting the benches to being fish storage, so I can keep them from filling up the floor.

Yeah, my benches will be storage to - probably camping stuff - not much into fishing.

Paul, where are you based?

We're hoping to do a week or two next year on Loch Lomond with this tub.

Tim.

Posted: Mon Aug 08, 2005 7:35 pm

by PaulMcClure

Tim,

I'm about an hour away from Loch Lomond, in Skelmorlie which is near Largs. If you are going to be up this way then give me a call. I'd love to see your boat. I've had the C17 plans since they were released and had planned to start building it a year ago. However my workshop got flooded while I was building an SH14 which got ruined, so I had to wait until some ground works were completed.

I built an FL14 a couple of years ago and I'm just finishing off an N7 this week. Once the C17 is done I'm thinking about a DE25 long cabin. And I suppose I should do another SH14. I still have the water damaged panels to use as tempates.

This boatbuilding stuff is addictive, no?

Posted: Tue Aug 09, 2005 4:14 am

by WobblyLegs

PaulMcClure wrote:Once the C17 is done I'm thinking about a DE25 long cabin.

You're reading my mind!

Re: 8 May

Posted: Tue Aug 09, 2005 7:49 pm

by attownsend

WobblyLegs wrote:So, this weekend has been a little more relaxing, but still keeping ahead of my schedule.

Stringers laminated, measured and cut, in that order, then notches cut. Followed by notches cut into frames "C," "D" and "E."

I had to check whether they all fit:

It's also the first real indication of the size of the boat that I'm building. Somehow a tape across the ground showing 17 feet doesn't mean anything!

I had planned on laminating the transom, but got hit by a thunder-storm with hail like I have never seen (in England) before? (20 minutes after this pic was taken, the sky was black. Unbelievable!).

More pic's in the gallery as usual.

Most excellent,Evildwarf.Build on!

Posted: Tue Aug 16, 2005 6:57 am

by WobblyLegs

The boat is now reaching full size.

A week of steady progress since the last update!

I have managed to fair the side panels of the boat, creating a load of dust, but the neighbours seem quite tolerant so far - lucky for me. In fact, they are more intrigued than anything else, always asking when the floods are coming, and making comments about arks etc.

So, after smoothing the sides, applied a fairing mixture to the bottom, trying to keep it as thin and smooth as possible, but I'm still going to have a lot of sanding to do.

Also, I've taken the spray rails out of their two week soak (it was going to be one week, but you know how it goes...). Even though the wood was thoroughly saturated, it still took a major effort to bend and twist them along the chine. In order to keep the rail from pulling away from the chine, I put a little (5mm) bolt through the front of it and the hull, then loads of screws from inside into the rail to hold it in place while it dries. More filling to do later.

The rail is going to stay there until properly dry (and hopefully hold it's shape) while I work around it.

The next parts to go on are the upper side panels. Last night I did a proper dry-fit, screwing the panels into place, starting at the transom and fastening every 500mm towards the bow. That seems enough to hold it. I might put more screws in when gluing, just to hold the panels together more uniformly.

Once again, I'm impressed with how well everything is fitting together. After reading on one of the posts here a while back that the overlap of the side panels is 6 inches, I made a mark 6" up (down if right-side up) the lower side panel midway along the boat, and another one midway between there and the front. Then a single screw through the back end of the panel into the transom for the panel to rotate on. I aligned the panel against the midway mark, then against the forward mark, the screwed into place. First one went on perfectly. Second one need a couple of screws removed, a little nudge, then together again. Perfect. Everything lines up very nicely at the front.

I think this pic shows much of what I've done during the past week.

So now I will be working on gluing the uppers, then taping to the transom and at the front, then the rubrail before returning to sanding the bottom.

We shall see how it goes.

More pics in the gallery:

http://gallery.bateau2.com/thumbnails.php?album=286

Keep building.

Wobbly.

Posted: Tue Aug 16, 2005 9:18 am

by tech_support

The bottom looks very fair from the pictures - nice job

Posted: Tue Aug 16, 2005 11:04 pm

by Mike Adams

Hi Wobbly,

I've been following your build with interest, especially now I've virtually finished the FL14 and am hoping to start on the LB22 soon. Thanks for some very informative photos - particularly of the strongback and your use of the laser level, which I found very helpful.

I think you are doing a terrific job - beautiful work on the hull, which looks as fair as one could wish for.

BTW, whereabouts in London are you? I was born in Hendon; also lived in Greenford for a while. I'll be in London (Watford/Bushey area) in early October, but unfortunately won't have a lot of time or I would try to come and visit you and see your boat "in the flesh".

Again, great work - keep posting pics!

Posted: Wed Aug 17, 2005 3:05 am

by Barney

that is an impressive piece of workmanship

Posted: Mon Aug 22, 2005 6:42 am

by WobblyLegs

The hull is finished.

Well, it's all glued together. I have to tape the bow, and the corners of the transom to the upper side panels, and then the structure is complete.

Loads of screws went into it to hold the upper side to the lower side while the glue cured, so I have most of those still to fill. The boat looks more like a sieve than a boat at the moment.

But, it does really look like a boat now. Not a pile of wood. It feels like I've reached a point where I'm starting to

finish a boat as opposed to

starting to build a boat.

Now, if only the weather would co-operate. I know I go on a bit about the rain, but it seem like each day of rain delays me by two or three days of progress as I have to wait until everything dries out. I've been hoping to seal the entire hull with epoxy for days now, but it always seems to rain the day before I'm able to do it.

Next time I do something like this, I guess I should seal the wood (as suggested here before) before building, or maybe move to a drier place (which is also quite possible - a DE25 in South Africa is an idea brewing at the moment).

Anyway, I'm sitting with a boat, waiting for the weather to turn so I can finish off the outside of the hull. Let's hope it does, as I've decided to take next week off so that I have nine days dedicated to it.

I'll let you know how it goes.

Wobbly.

Mike Adams wrote:BTW, whereabouts in London are you?

Mike, I'm in Worcester Park, just beyond Wimbledon. It's a very wet place right now

Posted: Mon Aug 22, 2005 1:03 pm

by circlehook

very nice cant wait to see her flipped over

Posted: Mon Sep 19, 2005 5:09 pm

by WobblyLegs

circlehook wrote:very nice cant wait to see her flipped over

Yeah, me too, but not this year.

So, it's been almost a month since the last update...

So, it's been almost a month since the last update...

What can I say, it's been raining for most of it.

But, I have managed to get a bit further on the boat. I took a week off work at the end of August to concentrate on the hull. The weather co-operated perfectly, and I managed to sand the entire bottom of the hull, which took three days (about 4 hours a day was all I could manage) and 42 sanding disks-

Also, laid some FG tape along the keel, continuing up the bow to just under (if the boat was right-side up) the spray rails. Two reasons for this - one is to give the keel some protection from grounding, and secondly, running it over the corner towards the bow gives me more lee-way when sanding that curve smooth, and avoiding sanding into the bi-ax. It worked perfectly, and will probably give a tiny bit more protection against hitting debris that often floats down the Thames. -

Lastly, I have (eventually) joined the spray rails and strakes to the hull. I put a post on the process of shaping the front of the strakes

here as I thought it might be useful for other builders. The strakes I did last week with the assistance of Mrs. Wobbly - she held them in place while I pulled them down with screws from inside, and the spray rails went on yesterday, with myself holding them in place on the outside, an assistant holding the long end up, and another assistant to push screws in from inside. Went smoothly.

It did help that I'd soaked the rails, then put them in place to dry. When I removed them, they kept a very nice curve, not quite a perfect match to the hull, but nearly.

The season's changing now, very definitely heading into autumn, so I'm planning on covering everything with a layer of epoxy, wrapping it all up under a new tarpaulin (my present one now has loads of holes in it) and pulling the tent down for the winter (it won't stand up to the wind that usually comes in late autumn).

If, after that, I manage to get a bit of sanding done here and there (there's lot's of finishing touches to do before painting), I consider that a bonus, but I'm not counting on it. With the arrival of spring next year, I'm looking forward to putting some colour on the boat.

Well, that's my progress for five month's of building my C17. A lot of the time I've been held back by weather, but the last month or so has been a case of doing something while opportunity presents, and find something else to do when it's wet (not that easy to do). I will put more updates here as things go on, but don't hold your breath until about March/April 2006.

As usual, more pics

here.

Later.

B.O.D.

Wobbly.

Posted: Sun Oct 30, 2005 1:04 pm

by WobblyLegs

Well, that's it for this year

So, a pic of this summer's progress:

And, now it's wrapped until spring:

Have a good winter peeps (I'm going looking for some piste soon!).

Wobb.

Posted: Sun Oct 30, 2005 2:17 pm

by MadRus

No! No! No! It's going to kill me to have to wait to see this one finished. Heve a nice nap.

Posted: Sun Oct 30, 2005 5:14 pm

by Mike Adams

Wobb,

That's a BEAUTIFUL hull! Well done. Looking forward to seeing you resume work in the Spring. Until then, take care.

Mike

Posted: Sun Oct 30, 2005 6:44 pm

by SurfRider

WobblyLegs wrote:Well, that's it for this year

And, now it's wrapped until spring:

A more patient man I have never seen.

Posted: Mon Oct 31, 2005 12:43 pm

by Lucky_Louis

Looking great Wobbly! I fully understand the challenges of building outside in our Northern climes. I would like to share what happened to me last winter so the same doesn't happen to you this winter. When I resumed my OB17 build this spring, I peeked up into my hull only to find a bumper crop of mildew had taken hold everywhere. Apparently the stuff loves mahogany. Before this winter takes hold, I'm going have a few hours of scrubbing with bleach before I can dry and seal with epoxy. I'm not really ready to flip my hull yet but I may flip, seal the inside, and flip back onto the mold before winter. A light bulb for a bit of heat and a small fan for air circulation may work too.

Posted: Mon Oct 31, 2005 1:04 pm

by WobblyLegs

Lucky_Louis wrote:Looking great Wobbly! I fully understand the challenges of building outside in our Northern climes. I would like to share what happened to me last winter so the same doesn't happen to you this winter. When I resumed my OB17 build this spring, I peeked up into my hull only to find a bumper crop of mildew had taken hold everywhere. Apparently the stuff loves mahogany. Before this winter takes hold, I'm going have a few hours of scrubbing with bleach before I can dry and seal with epoxy. I'm not really ready to flip my hull yet but I may flip, seal the inside, and flip back onto the mold before winter. A light bulb for a bit of heat and a small fan for air circulation may work too.

Lucky_Louis, thanks for the the advice. I'll make sure that I do periodical checks through the winter.

Most of it on the outside is sealed, and the inside is very open to air circulation (and easy to access), but it's no problem to keep an eye on it.

To the other responses to this "blog" through the summer - thanks guys, this site has been a mine of information, and the responses have been great!